With over 50 years of experience in the field of electro optics, shaped by extensive collaborations and strategic partnerships with leading defense OEMs, we are a trusted partner for our customers, providing innovative thermal imaging solutions, unrivalled expertise and supporting major defense platforms worldwide.

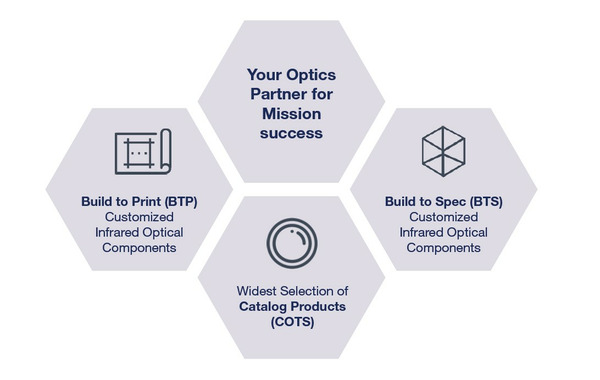

Thanks to our track record of designing and supplying thousands of thermal imaging optics for various defense applications, we have earned recognition as one of the world's leading one-stop-shop providers of infrared thermal imaging assemblies and components for defense OEMs.

Our dedicated R&D engineering team collaborates closely with defense customers, leveraging our extensive experience to develop, design, and deliver high-performance optics tailored to meet the stringent requirements of high precision and environmentally challenging defense applications. Our optics are perfectly aligned with the evolving needs of defense customers, and facilitate the deployment of today's most advanced aerospace and defense solutions.

- Ground-based: Anti-drone IR systems (C-UASs), Enhanced Vision Systems (EVS), Driver Vision Enhancement (DVE), Situation Awareness Systems (SAS), Remote Controlled Weapon Stations (RCWS), Tank Gunner/ Commander Sight, Thermal Goggles, Thermal Weapon Sight (TWS), Hand-held Thermal Imagers (HHTI)

- Airborne: Unmanned Aerial Vehicles (UAV), Payloads and Forward-Looking IR Cameras (FLIR)

- Naval: Surveillance, Targeting

- Missiles: Optical build-to-print components for IR guided missiles, including domes, mirrors and Cassegrain telescopes.

Discover a comprehensive selection of LWIR, MWIR and SWIR lenses in Single FOV, multiple FOV, and zoom configurations. Our product catalog features IR complex lens assemblies with various focus mechanisms including fixed, manual, motorized focus and continuous zoom options. Backed by years of expertise, Ophir's renowned motorized zoom lenses ensure industry-leading performance. Review product catalog>

Harnessing innovative designs to provide the largest portfolio of products with field-proven performance, answering the strict demands of global defense customers for:

- Lightweight, compact designs answering the strict SWaP restraints

- Rugged design for durability in the harshest environmental conditions

- Outstanding detection, recognition, and identification (DRI) ranges

- Accurate Line on Sight (LOS)

- High precision optics with MTF close to the diffraction limit

- Focal length ranges from 1.8mm to 1350mm

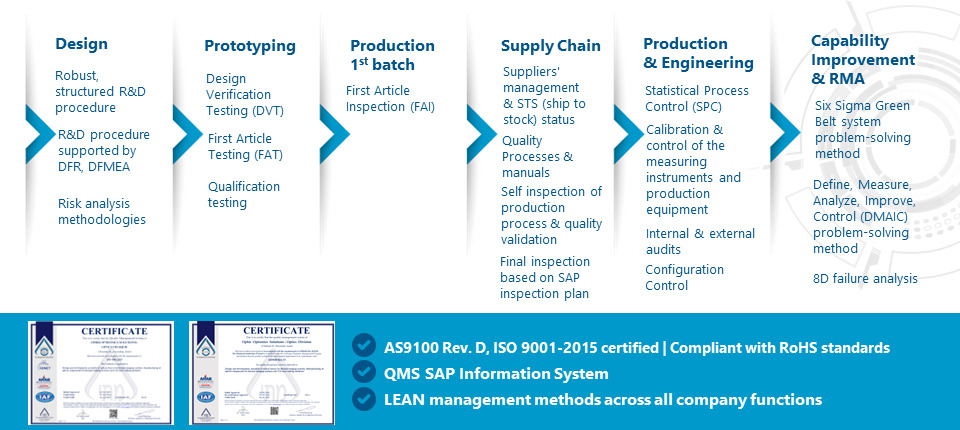

With rigorous QA testing throughout the production process, we ensure that any finished product is optimized for the defense market requirements. From design to delivery, our material control, in-process testing, operator inspections and final inspections all ensure that Ophir's products meet the highest specifications and quality standards.

- AS9100 Rev. E and ISO 9001:2015 certified

- US and European military standards compliant with: DIN 3140; IPC 620; MIL-PRF 13830; MIL-PRF 85285; MIL STD 810; MIL-C-48497; MIL-C-48616; ISO 10110 sections 1-19, ANSI\ASQ Z1.4

Utilizing advanced optical design technologies and innovative engineering, we excel in build-to-specification (BTS) processes, providing an efficient design with fewer elements, lighter components at reduced-cost.

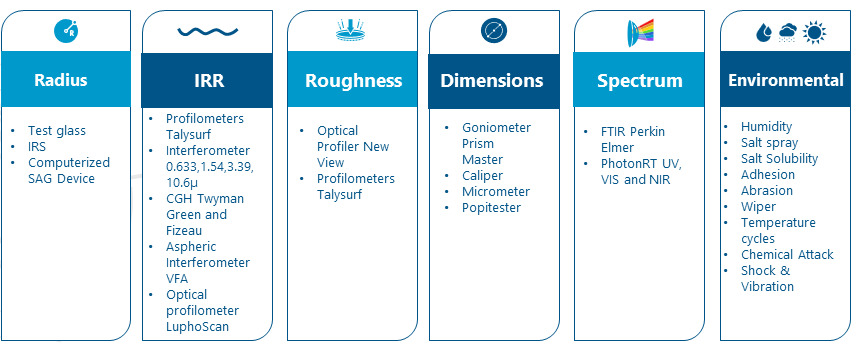

With cutting-edge manufacturing technologies such as MRF technology, diamond-turning machines, CNC generators and polishers, automated coating chambers, and advanced metrology and test equipment we produce high-performance components with tight tolerances, including aspheric, diffractive and spherical lenses, mirrors, domes, windows and prisms. Learn more>

- Lenses, reflective optics, domes, windows and prisms

- VIS to LWIR wavelengths.

- Spherical, aspherical, diffractive, flat, and freeform shapes.

- Doublets or triplets

- Substrates: Germanium, Silicon, Zinc selenide, Zinc sulfide (IR & multispectral), Calcium fluoride, Chalcogenide materials such as IG materials

- In-house, cutting-edge manufacturing technologies:

- MRF technology

- Lupho Scan Profilometers technology

- Diamond turning

- CNC polishing

- Coating

- Metrology

- Highest development standards including Design for Manufacturability and Assembly (DFMA) as well as highest production standards including risk analysis.

- Complete control of production processes

- Statistical Process Control (SPC) over full production cycle

- Innovative engineering

- Large volume high-end production capabilities

- Manufacturing sites in Israel and Europe (Romania) with a clean room for the coating, inspection and packing processes.

- MRF strict irregularity

- Large optics up to 400mm dia

- Dual A-spherical elements

- 5-400 mm diameter components fabrication and coating

- Free form (non-radial or matrix)

- Off axis parabolas

- Special truncated shapes

- Doublets and triplets

- Prisms of all types

- Mass production of low-cost IR small lenses

|

Windows |

Lenses |

Mirrors |

| Dimensional |

± 0.05 mm | ± 0.01 mm |

|

Surface figure (P-V)

|

Flatness 0.5 | 0.2 Fr

Irregularity 0.2 | 0.1 Fr |

Spherical

Power 2 Fr | 1 Fr

Irregularity 0.5 | 0.2 Fr |

Aspherical

Radius tolerance 0.1% | 0.05%

Irregularity 2 | 1 Fr |

Flatness 0.5 | 0.2 Fr |

| Parallelism |

3 | 5 arc sec |

|

Surface quality (S-D)

|

80-50 | 10-5 |

| Roughness nm, RMS |

2 | 0.5 |

Large reflective optics are essential for high-performance multispectral imaging systems in defense, surveillance, aerospace, and commercial applications.

Our expertise lies in producing and assembling precise, large reflective optics using advanced CNC grinding, polishing, and diamond turning techniques. These reflective optics are available in spherical, aspherical, parabolic, and freeform shapes, fabricated from materials such as aluminum, silicon, germanium, and copper.

With strict accuracy and surface quality standards, Ophir's reflective optics meet the rigorous demands of multispectral imaging applications across visible, UV, and IR wavelengths.

High-end specifications

- Diameters up to 700 mm

- On or off-axis mirrors

- Radius tolerance of 0.05%

- Irregularities less than 0.5 Fr P-V, 0.1 Fr RMS at 0.633μ

- Roughness less than 40 Å RMS

Read whitepaper

Coating types:

- Anti-reflective (AR), Mirrors and Filters

- UV, VIS, NIR, SWIR, MWIR, LWIR

- Multispectral coatings

- High efficiency and high durability coatings

- DLC (HC) coatings and Low Reflectance HC (LRHC)

- Laser coatings YAG and CO2

- EUV coatings

Coating performance:

- Broadband AR: Ref<0.5% to 0.2% Tra >98% to 99%

- Broadband mirror: Ref>98% to 99%

- Windscreen Wiper Test TS1888 / P 5.4.3 – DLC coatings

Knowing firsthand the unique challenges posed by wet, humid, and salty coastal environments, we have meticulously crafted the new AquaShieldIR lens coating to tackle the challenges of maritime environments head-on. With its advanced hydrophobic properties, the AquaShieldIR lens coating provides unparalleled protection and boosts the performance of your IR imaging system for the long run. Read more>

Ultra-High Velocity

Ultra-High Velocity