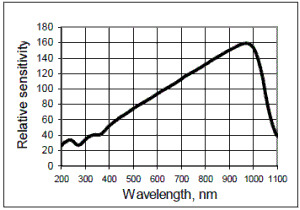

Photodiode detectors are very sensitive, have a wide dynamic range and are very linear at low powers. However, they are very wavelength dependent as shown in the graph, necessitating calibration over a complete range of wavelengths. They also saturate at low powers, becoming nonlinear. Therefore this type of power meter is mainly for low powers. With no additional filters, they are linear up to a few mW and with filters they can measure as much as 3 Watts.

The third type of detector is the pyroelectric detector consisting of a crystal that polarizes when heated. These detectors operate as follows:

When a pulse of light hits the absorbing surface of the detector, it heats up and polarizes the crystal, thus creating a equal and opposite charge on the two surfaces of the detector. The detector surface is metalized so the charge is collected onto the parallel capacitor no matter where the laser beam hits the surface. The charge on the capacitor is thus proportional to the pulse energy.

After the pulse is over, the voltage on the capacitor is read and the capacitor is electronically discharged to be ready for the next pulse.

Pyroelectric detectors are particularly useful for repetitive pulses and can measure up to thousands of pulses per second. They are also quite sensitive. They are not particularly durable, however, so for higher energies and powers, an attenuator/diffuser is placed in front of the sensor crystal to lower the energy on the pyroelectric crystal.

While the basic measurement technology, as explained above has remained the same, lasers and laser systems have advanced in a number of ways thus necessitating improvements in power/energy measurement devices.

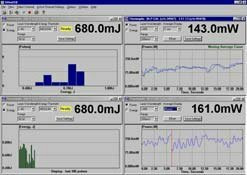

Lasers and laser systems have become more precise and system requirements for exact power or energy have become more demanding. If ± 10% in power was formerly acceptable then today in many instances a need for controlling a laser based device to ± 5% in absolute accuracy and ±1% or better in stability are common. Today, there are applications that need to measure pulse to pulse stability to 0.2% accuracy. Lasers have become more powerful. Today we have commercial or medical lasers putting out 300 Joules per pulse or powers of 10Kilowatts. We have concentrated beams with up to several hundred Joules/cm² or over 10KW/cm². These powerful and concentrated beams challenge the most durable power/energy meters. Lasers have proliferated and have become more diverse. We have today lasers of a tremendous variation in power, energy, wavelength, beam size and repetition rate. We have powers from picowatts to 10s of kilowatts, energies from picojoules to hundreds of Joules. We have beam sizes from very small to meters in diameter and repetition rates to tens of kilohertz. We have lasers from the far UV to the far IR. Power and energy measuring devices have to deal with this variety as well as possible. An example of a new type of source for which a measurement solution will be found is Terahertz lasers.

Although, as noted, the basic technology has not changed, over the last 10 years, laser power and energy meters have advanced to meet these new demands of new laser systems.

For one thing, there has been more specialization, where specialized power and energy meters have been developed for diverse purposes. There are photodiode power meters that catch the peak power and are useful for measuring scanned beams as in bar code scanners. There are photodiode detectors in an "integrating sphere" that catch uncollimated light radiating in various directions to measure total integrated radiation. There are special geometry meters that are designed to get into tight locations. There are meters to measure the pulsed light of IPL hair removal medical devices, meters to measure the light in photolithography machines and many other examples.

New general purpose power meters have also been developed to meet the demands of the proliferation of powers and energies both on the low end and high end.

There have been dramatic increases in resistance to damage. New coatings and absorbers capable of standing up to very high energies have been developed. Today there are power measuring surfaces from several manufacturers claiming more than 100KW/cm² damage threshold for moderate powers. There are power and energy measuring heads able to withstand hundreds of Joules/cm² especially for long pulse lasers.

There are also new devices for the low end. There are broadband power meters capable of accurately measuring tens of microwatts or microjoules. Accuracy has also been improved. Accuracy of power or energy is now routinely quoted as ±3% and in some cases better than that. Stability of some energy meters is better than 0.2%. Manufacturers have perfected ways to more accurately calibrate power and energy meters. They have more laser wavelengths available for calibration and a wider range of powers and energies as well as more accurate calibration equipment.

Some examples of new power/energy meters that have been developed to meet increasingly varied needs are shown here. At one end of the scale is a broadband thermal power meter that can reliably measure down to 50μW average power and single pulse energy down to 15μJ. At the other end of the scale is shown a power meter that can measure up to 10,000W at power densities of 10 kW/cm².

Ultra-High Velocity

Ultra-High Velocity