Ophir has many years experience in supplying measurement systems for high power industrial lasers and has the highest power measuring equipment available on the market – up to 120 kilowatts. Ophir meters also have the highest damage threshold available – up to 10kW/cm² at 10kW. Ophir supplies water cooled sensors from 300W up to 120kW and air cooled sensors up to 500W.

All sensors supplied by Ophir have been tested at up to full power and their linearity verified over the entire power range. This is done by deflecting a fraction of the power with a beam splitter into a lower power sensor whose linearity has previously been verified by NIST or PTB. In some cases, it is done by measuring the reading over the power range against a higher power sensor that has been previously measured. The accuracy, linearity and damage specifications have been carefully verified over many years of development and use by the largest existing user base. In addition to power meters for high powers, Ophir also has beam profilers, beam dumps and protective enclosures for industrial lasers.

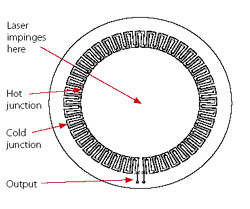

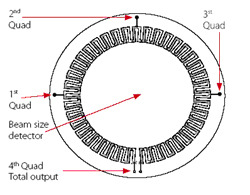

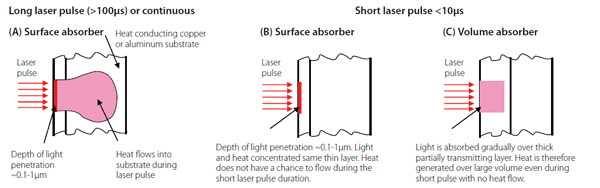

Ophir models 5000W, 10K-W, Comet 10K and 30K-W are calibrated using relatively low power lasers not exceeding 1000W. Using laser powers that are in many cases much lower than the power rating of the sensors being calibrated raises the question of calibration accuracy. The following explanation clearly demonstrates that these highest power sensors are indeed accurate to ±5% over their measurement range as specified. The 5000W, 10K-W and 30K-W sensors work on the thermopile principle, where the radial heat flow in the absorber disk causes a temperature difference between the hot and cold junctions of the thermopile which in turn causes a voltage difference across the thermopile. Since the instrument is a thermopile voltage generating device, it must be linear at low values of output. Therefore, if it has been shown to be linear up to full power – as it has - it will necessarily be linear at very low powers and if the calibration is correct at low powers, it will remain correct at high powers as well. On the other hand, although the output may be linear at low powers, there may be a zero offset that, due to the relatively low output at low powers, will cause an error in calibration.

For example, if calibration is performed at 200W and the output of the sensor is 10μV/W (a typical value) and there is a zero offset of only 1μV, this will cause a calibration error of 10%. Ophir's calibration method always measures the difference between the reading with power applied and without power applied, thus eliminating error due to zero offset. This measurement is taken several times to insure accuracy. The above measurement method assures that the calibration inaccuracy due to measurement errors is less than 1%, comparable to the expected errors in our lower powered sensors. In order to verify this, all of our high power sensors have been measured by comparison to various calibration standards. These measurements have shown Ophir sensors to be well within the claimed limits of linearity. The Comet 10K series measures the heat rise of the absorbing puck when irradiated by the laser for 10s. In order to calibrate the Comet 10K, we simply irradiate with a lower power laser for longer e.g. 150W for 60s. Thus the heating effect is similar to that of a higher power laser. Tests of the Comet calibrated by this method vs. NIST traceable high power sensors has shown that it is accurate and reproducible.

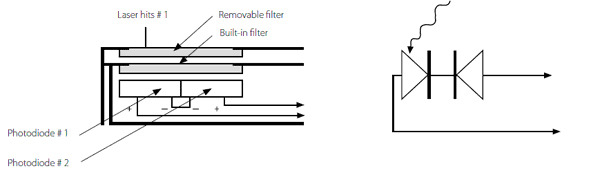

A photodiode sensor is a semiconductor device that produces a current proportional to light intensity and has a high degree of linearity over a large range of light power levels - from fractions of a nanowatt to about 2 mW. Above that light level, corresponding to a current of about 1mA, the electron density in the photodiode becomes too great and its efficiency is reduced causing saturation and a lower reading. Most Ophir PD sensors have a built-in filter that reduces the light level on the detector and allows measurement up to 30mW without saturation. Most sensors have an additional removable filter allowing measurement to 300mW or 3 Watts depending on the model.

When a photon source, such as a laser, is directed at a photodiode detector, a current proportional to the light intensity and dependent on the wavelength is created. Since many low power lasers have powers on the order of 5 to 30mW, and most photodiode detectors saturate at about 2mW, the PD300 sensor has been constructed with a built-in filter so the basic sensor can measure up to 30mW without saturation. With the removable extra filter, the PD300 sensors series can measure up to 300mW or 3W depending on the model. The Ophir power meter unit amplifies this signal and indicates the power level received by the sensor. Due to the superior circuitry of the Ophir power meters, the noise level is very low and the PD300 series sensors with Ophir power meter have a large dynamic range from picowatts to watts. The PD300 is shown schematically below. The PD300 and PD300-1W have the exclusive patented dual detectors connected back to back which eliminate any signal illuminating both detectors equally (background light).

Ultra-High Velocity

Ultra-High Velocity