Yoni Groisman, Application Engineer

Such material processing applications as welding, cutting, additive manufacturing, marking, and engraving are now performed using lasers, enabling higher precision, faster rates, and increased variability. In addition to the material processing industry, increased use of high-power lasers is also seen in military and research.

Traditionally, high power lasers were CO2 pumped lasers. Recent developments and market requirements for more accurate processing have turned NIR fiber lasers into a rapidly growing player in all high-power applications, including processing, research, and military.

Lasers are considered “high power” if their output is in the range of hundreds of watts to tens of kW. The vast majority of material processing lasers are 1070 nm fiber lasers, and rarely green 535nm fiber. CO2 lasers are still popular with in types of material processing, but these are being phased out in favor of fiber lasers. Ultrafast lasers (with picosecond and/or femtosecond pulse widths) are also starting to be employed for finesse material processing operations.

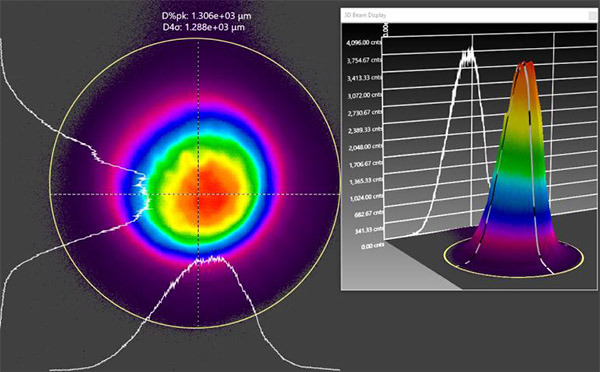

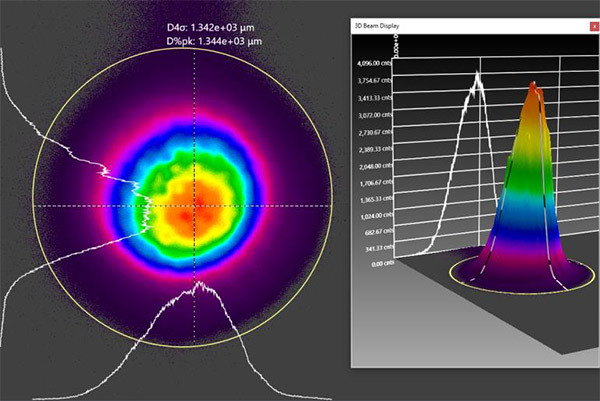

The most common types of high-power CW fiber lasers have output powers ranging from 1 kW single mode to over 100 kW multi-mode. Their reliability, flexibility, and wide variety of interchanging fiber terminations, collimation optics, and processing heads (with both Gaussian and Top Hat beam shapes) make fiber lasers most suitable for the material processing industry.

Importantly, the variety of applications and production rates require periodic checkups or constant tracking of parameters, to ensure process control and quality assurance. Parameters to be tracked include:

- Spot size

- Beam shape / Mode

- Focusing position

- M2

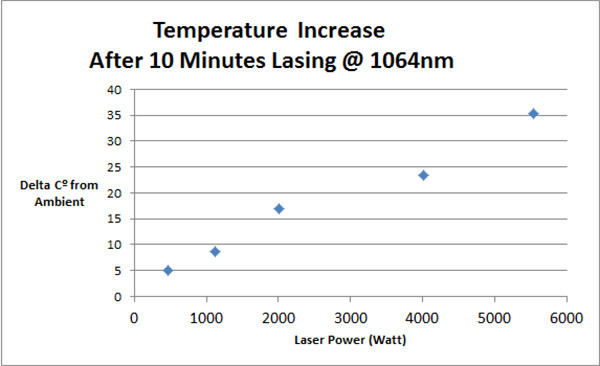

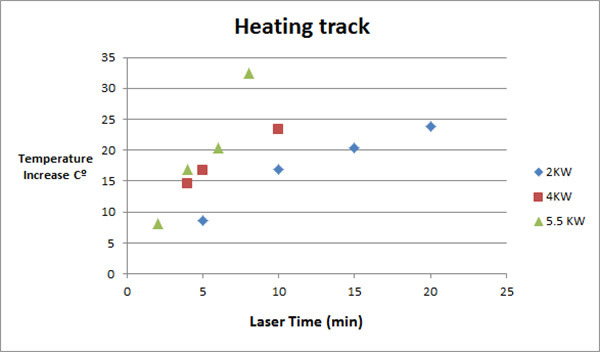

- Laser Power/ Energy

While laser power/ energy can be measured by a conventional thermopile sensor with water cooling, other parameters such as Spot Size, Beam shape, Focal position, and M2 require more advanced techniques to measure high power laser parameters without distorting them or damaging the analytical equipment.

In general, there are three methods employed to perform this task:

- Indirect measuring, without interaction with the beam. This technique is based on imaging of the beam’s Rayleigh scattered light from the side, which is used in the Ophir BeamWatch

- Scanning tip with a pinhole, which samples a small portion of the beam and presents it to a single element detector. The rotational and translational scanning of the pinhole through the beam creates a 2D image of the beam profile. This method requires large scale equipment with moving mechanical parts and a water chiller.

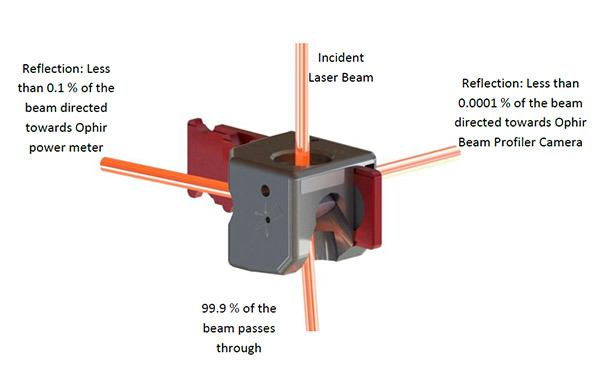

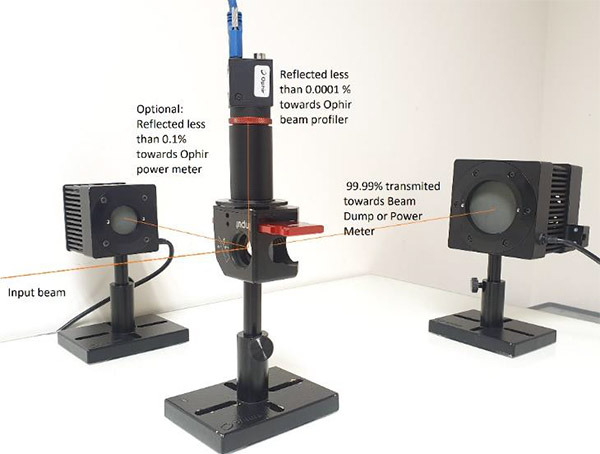

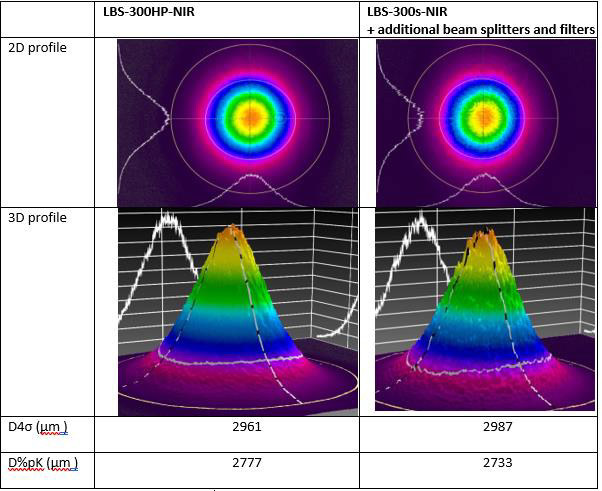

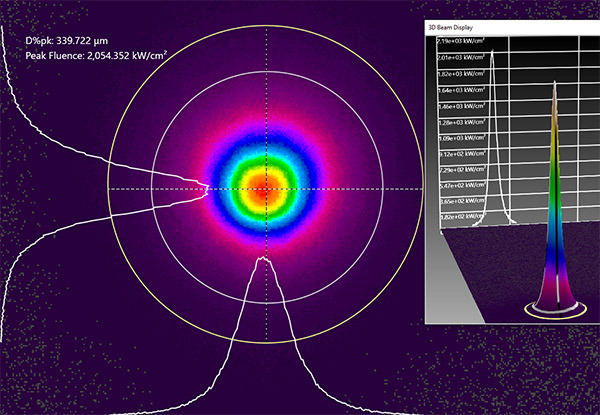

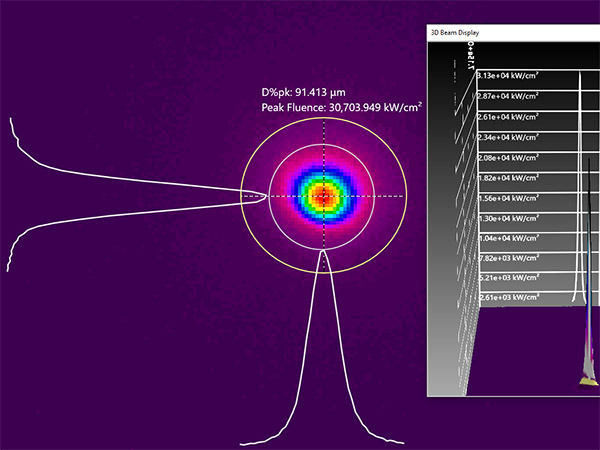

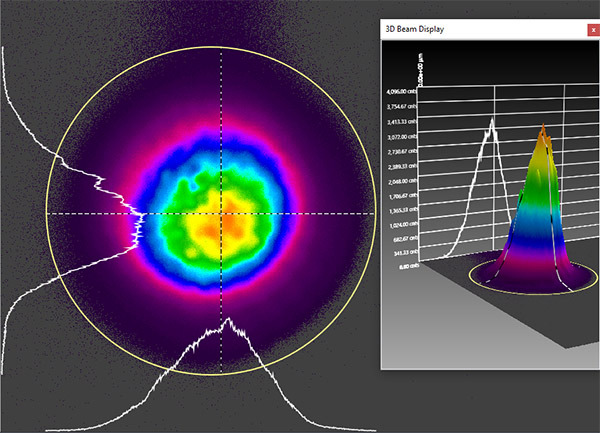

- Direct measuring with CCD beam profiler, after many orders of magnitude of optical attenuation. The new Ophir LBS-300HP-NIR beam splitter for high power lasers allows measuring NIR (1000-1100 nm) focused or collimated laser beams profiles up to 5kW or 15MW/cm2.

Ultra-High Velocity

Ultra-High Velocity