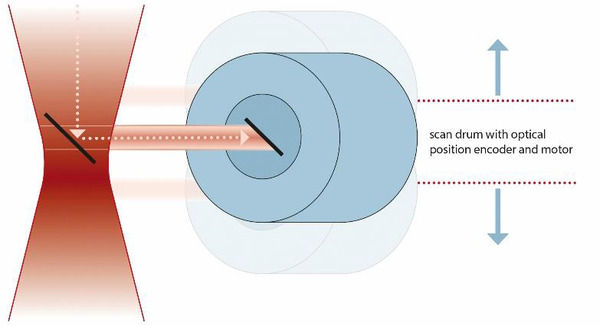

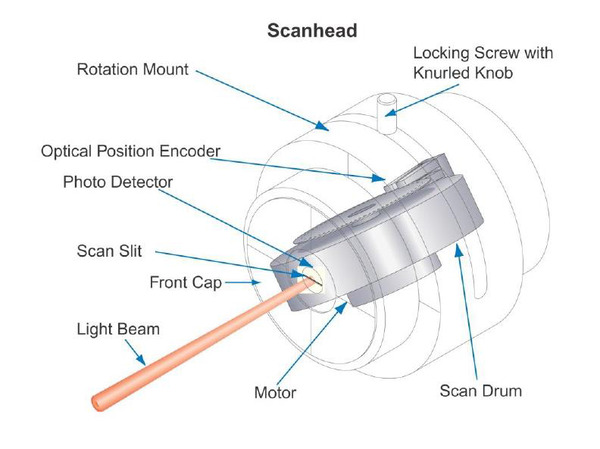

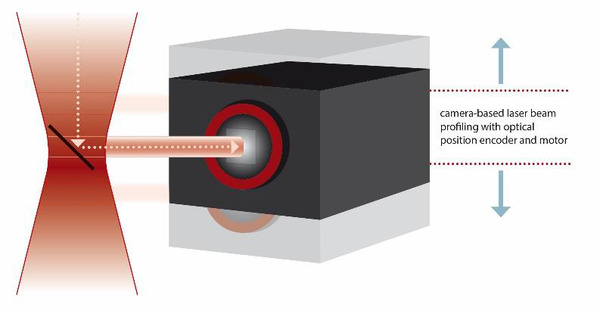

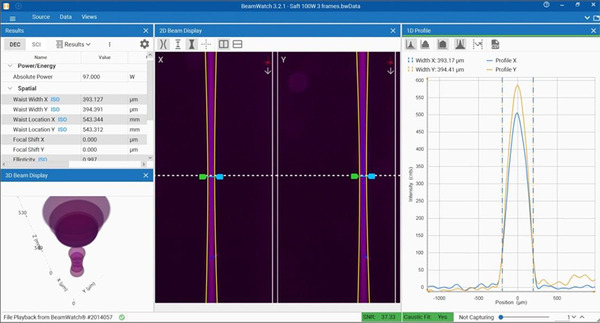

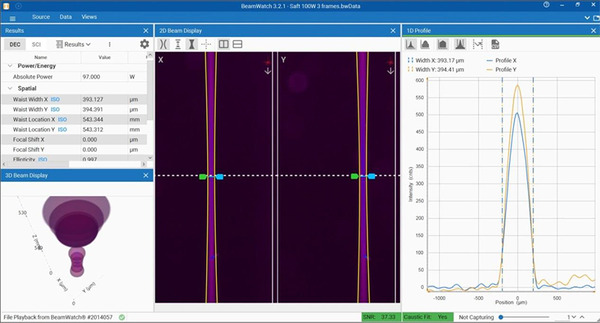

BeamWatch is a technology that produces measurements considered to be essentially equivalent to the measurements made with a scanning slit. In addition, the camera image used in the BeamWatch analysis is constituted of hundreds of individual slit measurements. Each row of data, or lineout, from the image of the caustic is considered to be equivalent to a scanning a slit measurement of the corresponding plane of the caustic. ISO 11146-1 beam propagation measurement requires the acquisition of second moment beam widths. ISO 11146-3:2004(E) provides for alternative measurement methods including the scanning slit method as outlined in section 4.4. Using equations 63 and 69 of ISO 11146-3:2004(E), scanning slit results can be converted to second moment results. In compliance with the ISO standard, the results presented here were calculated according to the conversion described in this section.

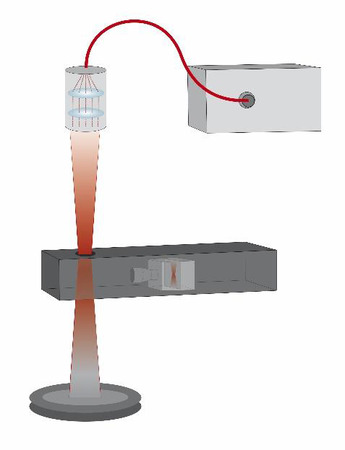

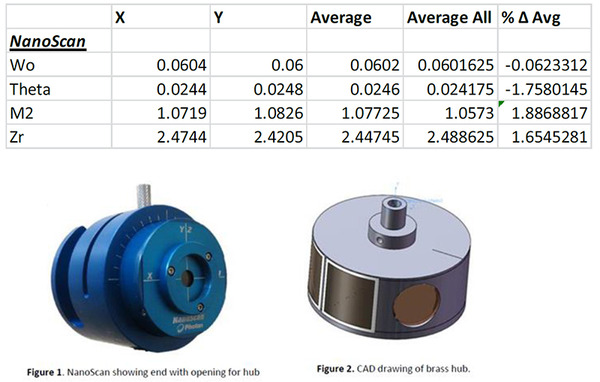

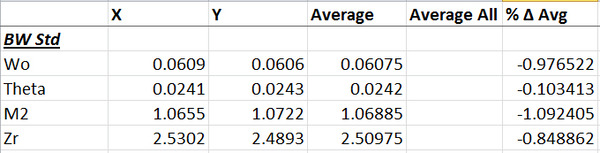

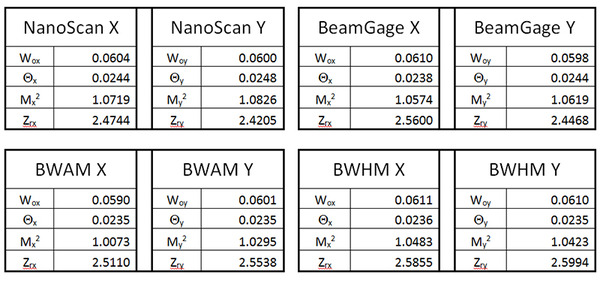

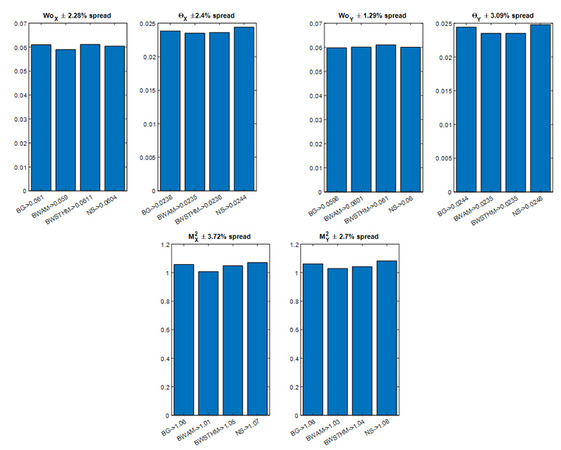

The measurements made with the various non-contact measurement devices based on Rayleigh scattering, BeamWatch and BeamWatch AM, meet all of the requirements of ISO 11146 including second moment beam widths derived from moving slit measurements. The maximum deviation from the mean for each of the three reported results (W0x, W0y, x, y, Mx2, and M²y) is less than 3.75%. There is excellent consistency between the four Ophir instruments tested employing three different technologies and four different calibration standards, giving confidence that BeamWatch based on Rayleigh scattering is a reliable technology for measuring beam quality. Although no official description of employing Rayleigh scatter in the ISO standard measurement of laser beam propagation characteristics exits, high power fiber laser users can be assured that results gained by using the non-contact beam propagation characteristic measurement technology will deliver reliable results that correlate well with measurements acquired with other techniques. In addition to the obvious compatibility of Rayleigh scatter measurements to further the understanding of high-power lasers, these devices benefit from significant advantages.

- Due to its non-contact nature there is no practical upper power limit for laser that can be measured with this technique.

- Rayleigh scatter is proportional to the inverse square of its wavelength so that while it is possible to measure the scatter from 1030 – 1080 nm sources, visible and UV sources provide many orders of magnitude more available signal.

- No moving parts and no direct interface to the laser beam equates to simplified preventative maintenance and no wear on beam splitter optics.

- Simplicity of the measurement setup will improve data integrity and comparability of data taken by different persons at different times or locations.

This new application of the Rayleigh scatter phenomenon offers the ability to assure documented performance of the focussed laser beam of high power fiber and IR laser systems with litteraly no upper power limit. By simplifying beam quality measurements, this technology promises that the quality and performance consistency of laser welding, cutting, and heat treating, annealing and additive manufacturing systems can now be assured easily and economically.

Camera Baseline: The image a camera produces when no energy is impinged on the sensor. The camera baseline contains noise the camera system produces when no external image or energies are presented.

Beam Profiler: A beam profiler is a measurement system that captures an image of a laser beam that represents the cross-sectional intensity distribution of the laser beam at a specific location along the beams propagation axis. Beam profilers are used to measure the size and location of a laser beam. Laser beam profilers can also be used to determine how the cross-sectional energy is distributed. How close to ideal beam distributions such as Gaussian (TEM00), donut mode (TEM*10), or Top Hat modes can be measured with some beam profiler systems.

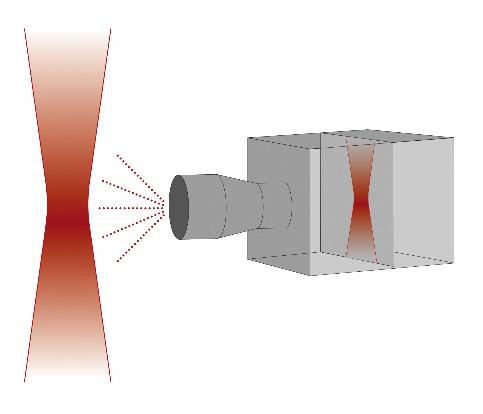

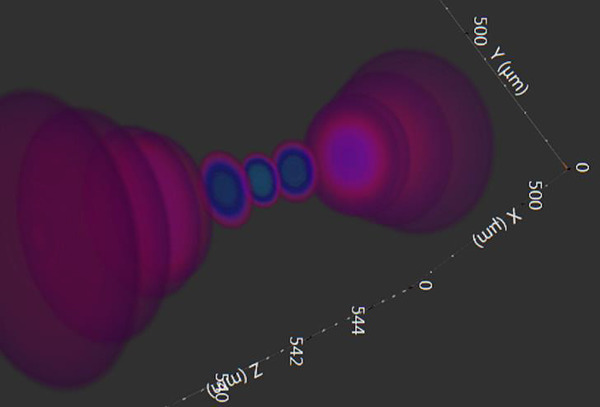

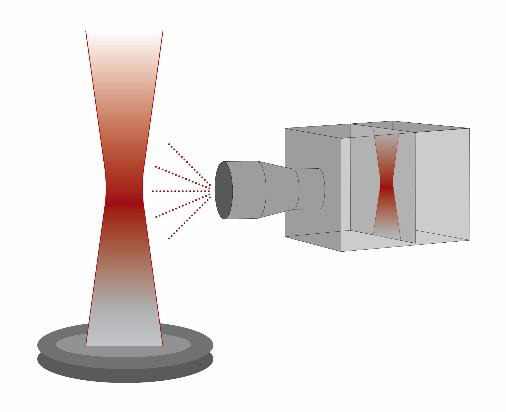

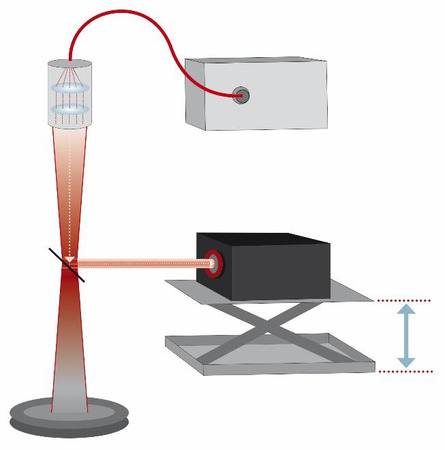

Caustic: The caustic in this definition is the segment of a laser beam that is focused. A focused beam caustic typically contains a number of Rayleigh ranges on both sides of the focal plane or minimum diameter of the beam. In some cases, a caustic is artificially created to measure the propagation characteristics of the laser being tested.

Rayleigh Range: The Rayleigh range is the length of the beam where the diameter changes by the square root of 2. It can also be stated that the cross-sectional area of the beam doubles. The Rayleigh range (or Rayleigh length) is typical measured from the beams waist but can also be stated as multiple Rayleigh lengths along the beam's propagation axis from the waist or focal plane.

Rayleigh Scatter: Rayleigh scatter is scattering of light or other electromagnetic radiation by particles much smaller than the wavelength of the radiation. Rayleigh scattering does not change the state of material. The particles may be individual atoms or molecules.

Second Moment Beam Width: Second Moment and D4sigma are used interchangeably in this document. Each refers to a description of a laser beam width that is 4 times σ, where σ is the standard deviation of the horizontal or vertical distribution. The ISO 11146 requires a Second Moment description of the laser beam width be used for measuring the propagation of a laser beam. The second order moment is defined as:

Ultra-High Velocity

Ultra-High Velocity