Derrick Peterman, Director of Sales, Ophir Photonics

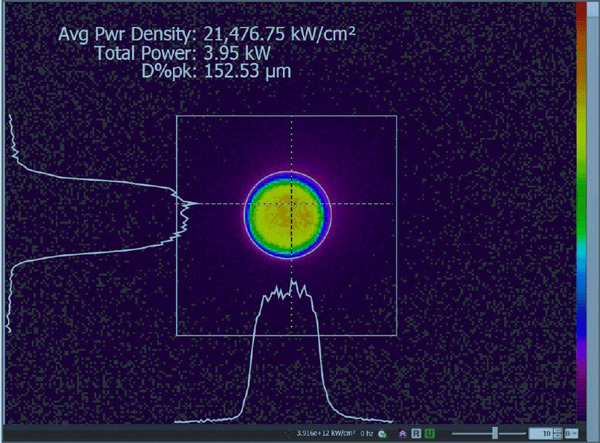

Consider profiling a 150 micron beam at focus from a 4 kW laser. The power per unit area at focus is a few megawatts (MW) per square centimeter. A CCD sensor saturates at ~1 microWatt per square centimeter. That means profiling a 150 micron from a 4 kW laser requires allowing only a few ten trillionths of the beam power to reach the bare CCD sensor inside the profiler, which is achieved through beam attenuation optics. Of course, the optics must not distort the beam.

Anti-reflection coatings used in standard beam attenuation optics have damage thresholds in the 100 kW per square centimeter range, so they are susceptible to damage in these applications. Finally, in order to determine the beam size at optical focus, the optical path of the beam through the attenuation to the CCD sensor must be known with high precision to ensure the beam profiler measurement plane is at the beam focus and that there is precise knowledge of the location of the measurement plane.

For these reasons, reliable profiles at the focus of high power lasers are elusive and difficult to obtain. Often, the beam is profiled off-focus where it is larger and easier to attenuate and capture. This provides some useful information about the laser system, but the focus is where the laser beam cutting, drilling, or welding actually takes place and can only be inferred through assumptions and guess work. Until now.

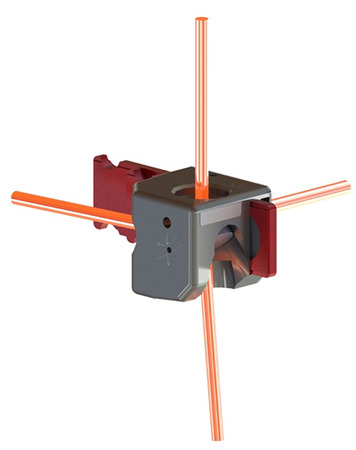

Ophir’s LBS-300HP-NIR beam splitter overcomes the challenges of profiling high power lasers at focus. It reduces extremely high laser power at an unprecedented 15 MW/cm2 at 5 kW. It reflects less than 0.0001% of the incident NIR beam while transmitting 99.9999%, keeping the original beam profile intact. This enables measurement of beam shape, focal spot, beam waist, and overall power. Each optical path through the LBS-300HP-NIR provides uniform attenuation of any beam shape (Gaussian, flat-top, doughnut, etc.) while preserving the polarization and overall profile of the incoming laser beam thus providing accurate sample of incident beam. This is enabling technology that, for the first time ever, allows camera-based beam profiling for high power lasers.

The result is a beam profiler system that easily measures high power beam at focus in a compact package. This system was used to capture a 4 kW fiber laser focused to a spot size of 150 microns (see Figure 1). The system measures beams as small as 37 microns.

The beam profile at focus, where the laser interacts with the material in a critical laser based manufacturing process, no longer needs to be guessed at. Instead, it can now be measured.

Ultra-High Velocity

Ultra-High Velocity