This trend is driven largely by growing demand for SWaP-C-optimized (Size, Weight, Power, and Cost) solutions across multiple markets. In defense, applications ranging from targeting systems to border surveillance increasingly require higher resolution and longer detection ranges – all while maintaining continuous zoom and line-of-sight (LOS) retention. In industrial applications, IR imaging is playing a critical role supporting new regulations in gas leak detection, homeland security, search and rescue, and smart infrastructure monitoring.

As a result, research projects that the global MWIR detector market will grow from $3.15 billion in 2025 to $7.07 billion by 2034, at a CAGR of 9.4%[2]. Similarly, the focal plane array (FPA) infrared detector market is expanding rapidly due to increased adoption in surveillance, environmental monitoring, and industrial automation.

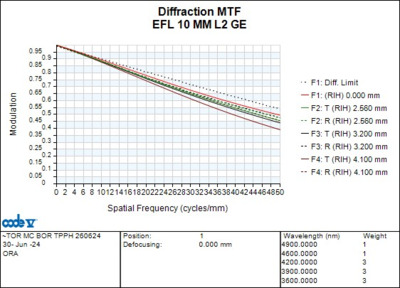

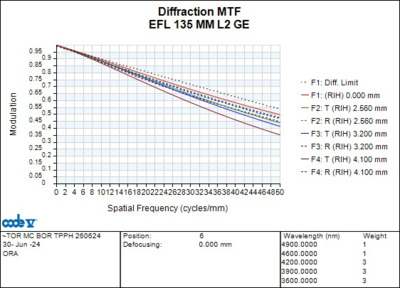

However, incorporating this new generation of smaller pitch detectors poses significant challenges for the imaging system designer. In particular, they require lower f number optics with improved modulation transfer function (MTF) at higher spatial frequencies in order to maintain image quality.

This makes it impossible to use the same lenses designed for larger pitch detectors without paying a performance penalty. Instead, achieving high image quality with these small pitch sensors demands more complex optical systems. These must be designed specifically for the task, and then fabricated to tighter optical, mechanical, and assembly tolerances.

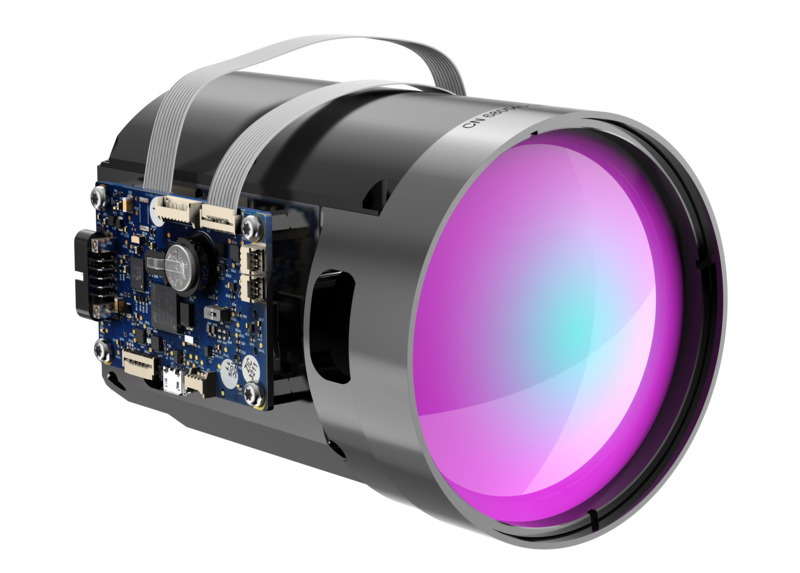

With its Ophir Infrared Optics product line, MKS addresses the challenges of building optics for smaller pixel pitch MWIR and LWIR detectors. This is achieved through a combination of advanced optical design, precision opto-mechanical engineering, and cutting-edge manufacturing, assembly and testing processes.

This whitepaper explores the optical issues involved in using small pixel pitch detectors. It then shows how Ophir IR lens solutions enable imaging system builders to take full advantage of these detectors, without sacrificing performance.

Infrared detector manufacturers have made significant progress in detector minimization over the past few years. MWIR detector array pixel sizes have gone from 15 µm to as little as 5 µm, and LWIR array pixels have shrunk from 17 µm to 8 µm.

These smaller pixel pitch detectors offer several potential benefits. One advantage is that reducing pixel size shrinks the physical size of a specific form factor detector (e.g. VGA or SXGA). This allows more devices to be fabricated on a single wafer which lowers the unit cost. This cost reduction is especially important for cooled MWIR detectors, where the focal plane array (FPA) is often the most expensive single component in the system.

Physically smaller MWIR FPAs are also easier to cool. Their reduced thermal mass allows for faster cooldown times, enabling more rapid system startup. These detectors also require lower steady-state cooling power, which reduces system size and energy consumption. In addition, smaller FPAs permit the use of shorter cold shield heights and shorter optical paths, which minimizes the amount of unwanted infrared radiation entering the system. This lowers parasitic thermal background noise and improves overall detector sensitivity.

Just as importantly, smaller pixel pitch opens new possibilities for system integration. Customers using older, larger pixel pitch detectors often face challenges such as bulky systems that are difficult to integrate into compact platforms, longer cooldown times with higher power consumption, and lower image fidelity at long ranges due to limited resolution. These issues reduce operational flexibility – especially in mobile, airborne, or handheld systems where SWaP-C constraints are paramount.

Smaller pixel pitch sensors address these limitations. For example, in UAV surveillance, they enable smaller, lighter payloads, supporting longer flight durations and faster startup. In handheld thermal imagers, they enhance portability and battery life, which is critical for field operatives. In border security, higher resolution improves long-range detection and identification even in harsh environments. These advantages – improved image clarity, higher thermal contrast, faster deployment, and better integration into multi-sensor platforms – are driving the shift toward smaller pitch detectors, particularly in SXGA (1280×1024) format.

However, not everything improves as pixels shrink. For example, smaller pixels collect fewer photons due to their reduced surface area. This lowers signal-to-noise ratio (SNR), which is particularly important in low-signal or long-range detection scenarios.

Smaller pixels also typically exhibit lower quantum efficiency, meaning a smaller percentage of incoming photons are converted into measurable signals. Plus, dynamic range tends to decrease with pixel size since a physically smaller pixel well holds less charge than a larger one.

Another issue is fixed-pattern noise. Manufacturing variation becomes more significant as pixel dimensions shrink, leading to greater non-uniformity in pixel response. This requires more aggressive calibration and correction in the signal processing chain, and even then, residual noise can degrade image quality.

Pixel-to-pixel crosstalk is also more problematic in small-pitch detectors. As pixel size approaches the diffusion length of the detector material, electrical and optical signal leakage between adjacent pixels becomes harder to control. This reduces spatial fidelity and further degrades MTF at the detector level, even before considering the optics.

Beyond just reducing cost and simplifying cooling, a smaller FPA also offers significant advantages in terms of optics, particularly the ability to improve SWaP-C optimization of imagers.

A primary reason for this is because, as FPA size shrinks, the lens focal length needed to maintain the same field-of-view is also reduced.

This can lead to more compact, lighter optical systems, as shorter focal length lenses usually consist of smaller components. More compact lenses can simplify mechanical design, and offer greater flexibility for integration into compact gimbals, handheld enclosures, or multi-sensor payloads. They can also enable lighter, faster zoom and focus mechanisms with lower actuation power and quicker response times.

Shorter optical paths even simplify certain aspects of athermalization and stray light control. For fixed field-of-view systems in particular, these advantages can translate into measurable reductions in SWaP-C at the system level.

These are the promises of smaller pixel pitch sensors. But in reality, obtaining these optical benefits is far from straightforward. In some cases, it may even be impossible.

One key issue is that shrinking the pixel size for a given FPA form factor necessitates the use of lower f-number optics. To understand why this is so, consider three key optical relationships:

Ultra-High Velocity

Ultra-High Velocity