High power laser beams are handled by using reflective materials, and the level of reflectivity, and thus its inverse, absorption, are dependent on the wavelength of the laser light. In general the long infrared wavelengths, such as that of the carbon dioxide laser at 10.6 microns, are highly reflective. These allow for the highest power measurements up to the maximum levels of several kilowatts. When measuring these lasers and power levels the principle concern is the heat buildup in the scan head. The surfaces of the measurement drum and slits are better than 98% reflective to this wavelength, and thus only 2% of the incident power will be absorbed by the scan head and heat it up. Nonetheless, at 5000 W this represents a heat load of 100 W that will raise the temperature of the internal components, and may cause damage to the detector and encoder electronics. The High Power NanoScan is designed to be used for short-term measurements at these power levels. The beam should only be incident on the scan head for a few seconds. The software is equipped with a record mode that makes it easy to make a short measurement and then review the data while the scan head is allowed to cool down.

The reflectivity of the system is around 98% for wavelengths from around 3 μm and above. Below this, between around 700 nm and 3 μm the reflectivity is around 96%. Although this is still pretty good, it means that the absorbance has doubled, and thus the power levels that can be handled are cut in half. From 700 nm to the ultraviolet wavelengths the reflectivity drops dramatically, to below 35% at 200 nm. "High power" in the UV is measured in watts not kilowatts. Consult the wavelength-corrected operating space charts to understand the how the High Power NanoScan should be used with your specific laser. These will give safe power levels that can be measured continuously and give recommended exposure time for powers above the safe levels in the different wavelength regimes.

The High Power NanoScan is based on the same operating principles of the standard NanoScan and its predecessor, the BeamScan. All of these systems use the moving slit measurement system, one of the strengths of which is the natural attenuation of the technique. It is only when the slit traverses the beam that light hits the detector. The standard NanoScan scan head, designed to measure beams up to a few watts, has blackened slits to prevent reflection back into the laser cavity. These systems use silicon or germanium detectors, which are sensitive enough to detect and accurately measure lasers with microwatt outputs in the UV, visible and near IR wavelengths. As the powers increase, it is possible to use a pyroelectric detector, which has the benefit of responding across the entire electromagnetic spectrum from UV to far IR. For beams up to 100 W (IR) the standard pyroelectric detector equipped standard NanoScan is a good choice. The pyro NanoScan uses standard alloy slits, but without blackening to increase the power handling capability by decreasing the absorption. This can be extended a bit by the inclusion of the optional copper slits. Copper is very reflective from 700nm to 3microns, and even better above 3 microns. In addition its heat transmission makes it ideal for high power applications.

The power that can be handled by the standard NanoScan is dependent on the wavelength of the light to be measured. The wavelength of light determines both its reflectivity from the slit surfaces and the energetic nature of the interactions with materials. As a rule of thumb, there are three basic wavelength regimes that govern how much power the scan head can handle1:

- 3 μm to FIR (>20 μm) –100 W maximum pyroelectric detector

- 500 nm to 3 μm—25 W maximum pyroelectric detector; 1 W germanium detector

- 190 to 500 nm—3 W maximum pyroelectric detector; 1 W silicon detector

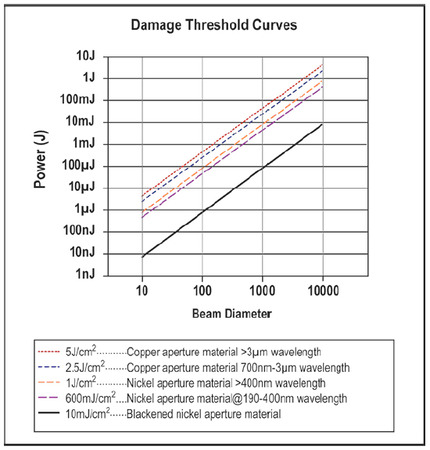

Power levels above these for any of these wavelength regimes can be considered "High Power." These values are total power capability of the scan head based on the overall heat load that the head can absorb without damage. The actual measurement capability for a particular beam is dependent on the power density of the beam to be measured in W/cm². The smaller the beam, the more concentrated the power density. The principle issue with power density is damage to the slit apertures and detectors. With small enough beams, powers well below the above limits will exceed the damage thresholds for the apertures. It is important to consult the operating space charts or slit damage calculator for information about specific beam diameters and measurable power levels.

Pulsed beams add an additional complication to the measurements of lasers. The NanoScan is capable of measuring higher frequency pulsed beams² but it is important to understand the effects of pulse energy as well as power. Pulsed beams usually concentrate the effective energy of the laser into short duration pulses, which increase the effect of the beam on target materials including the slits and detectors of the profiler. Changing the frequency of the pulses has a dramatic effect on the energy of the beam. Energy is measured in Joules and is calculated by the following formula:

Ultra-High Velocity

Ultra-High Velocity