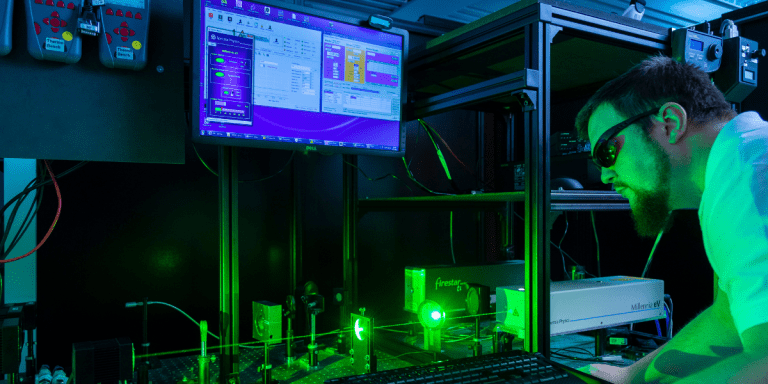

Imagine you’re responsible for a critical laser welding or cutting process in an industrial production facility, where high-power laser measurement is essential to guarantee process performance and stability. Say an automotive application or machine manufacturing.

You’ve had enough experience to know how important it is to monitor the laser’s behavior – there’s too much at stake to allow any laser performance drift to go undetected.

So, you start thinking: You want the right instrument. What will that look like – what does it need to do? What are some of its must-haves?

There are plenty of challenges you’ll need to address. The process creates lots of debris. The facility has various PLC’s from different generations – some with RS232, others based on advanced industrial protocols. It won’t be easy…

Well, clearly –

- It needs a rugged construction suitable for an industrial environment – such as protection from dust and process debris, and industrial grade connectors.

- Reliable performance is a must – it needs to provide accurate and repeatable measurements. A potentially expensive process might depend on it!

- Maybe at the moment you don’t need additional functionality besides just the measurement – but you certainly hope and plan to grow. The solution you choose should be flexible and modular, so that you’ll have a solution that does what you need now – and only what you need now – but leaves you the option of smoothly adding capabilities later.

- It should be easily integrated into modern automation systems – this is an industrial production line after all.

Well, you said you want the right instrument; and here it is.

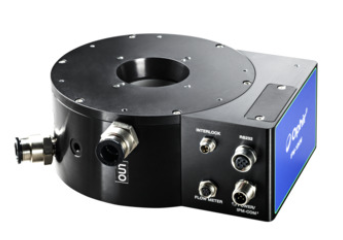

The Ophir IPM is a modular industrial laser power sensor for measuring the average power of high-power lasers up to 11kW. It’s ruggedized by design, with all the features needed for reliable, fail-safe operation in a tough operational environment. Its modular design provides the flexibility needed to address customers’ specific current needs, and to grow as those needs grow.

Let’s have just a quick look (you can find full details here):

It consists of 3 modules, 2 of which are optional.

1. The main module is the IPM-10KW sensor unit.

- It’s a water-cooled sensor, that can measure from 100W up to 11KW continuously, over the spectral range 900-1100 nm and 10.6 µm.

- The power readout (and the instrument configuration) uses the RS232 interface.

- There’s a safety interlock output for protection in case of overpower or cooling water failure, as well as an interface for an external water flow meter.

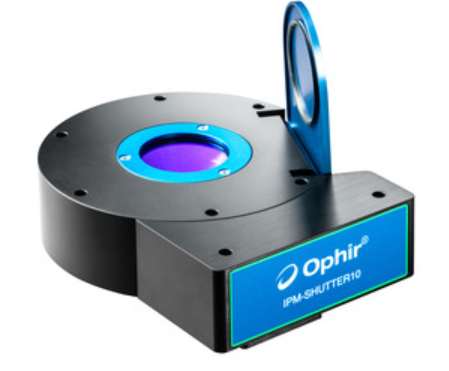

2. The 2nd module is an optional Automated Shutter module.

- It provides an electromechanical shutter that can be opened and closed remotely for protection when not measuring, and an antireflection-coated, field-replaceable window.

- The module gives the IPM an ingress protection rating of IP62.

- It also includes a scatter shield, which provides extra reduction of back-scattered laser power for maximum safety (and which also adds to the ingress protection of the instrument)

3. The 3rd module is an optional COM module, which serves as a communications hub.

- There is a choice of industrial protocols – Profinet and Ethernet/IP, with the industrial connectors coming in 2 flavors – AIDA and -M respectively.

- It has a web GUI, which enables easy configuration of the device, and allows smooth compatibility with the factory’s automation system.

Left: IPM-COM-EtherNet/IP

The modules are designed to be easily assembled together. That means you have the option of ordering them together or starting with the sensor module itself – and expanding your instrument later when you need the capabilities the other modules offer.

So, back to the scenario we started with…If you’re involved with laser cutting, drilling, and similar industrial high-power laser measurement applications, the Ophir IPM is really the ideal solution for keeping your process on track and under tight control.