Laser beam profiling is essential for maintaining consistent laser performance, optimizing industrial processes like welding and additive manufacturing, and ensuring safety and compliance with quality standards. It enables precise measurement of beam parameters such as focus, shape, and power, which directly impact the effectiveness and reliability of laser applications. Laser profiling also supports predictive maintenance by detecting beam drift or degradation before it affects production.

Why Beam Profiling Matters for High-Power Lasers

High-power lasers used in industry for welding, cutting, cladding, or directed energy military applications require beam profiling even more frequently due to harsh environmental conditions and stringent reliability standards. Measuring high-power lasers is sometimes challenging due to the effects of intense laser energy on the optical components used in beam profiling equipment, such as filters, lenses, and imagers.

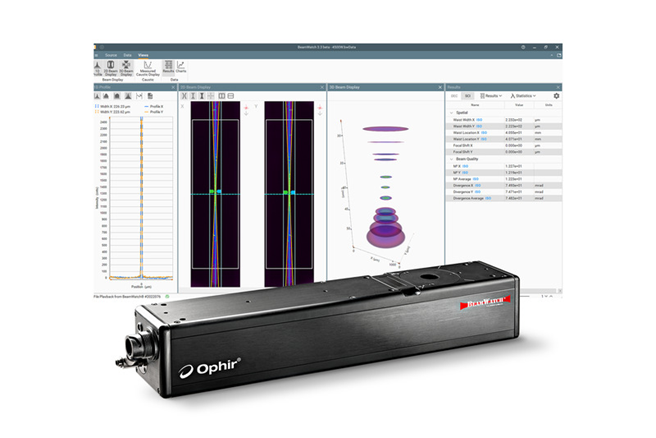

How BeamWatch® Works: Contactless Profiling with Rayleigh Scattering

BeamWatch, Ophir’s contactless beam profiling technology, offers several distinct advantages over traditional laser beam profilers, particularly in high-power industrial laser applications.

BeamWatch uses Rayleigh scattering to analyze the laser beam without physically intercepting it. This is especially important for high-power lasers, where contact-based methods can be damaged or produce distorted measurements due to the beam’s intensity. The system enables real-time monitoring without interrupting the laser process or requiring the removal of tooling—an important advantage in demanding industrial environments.

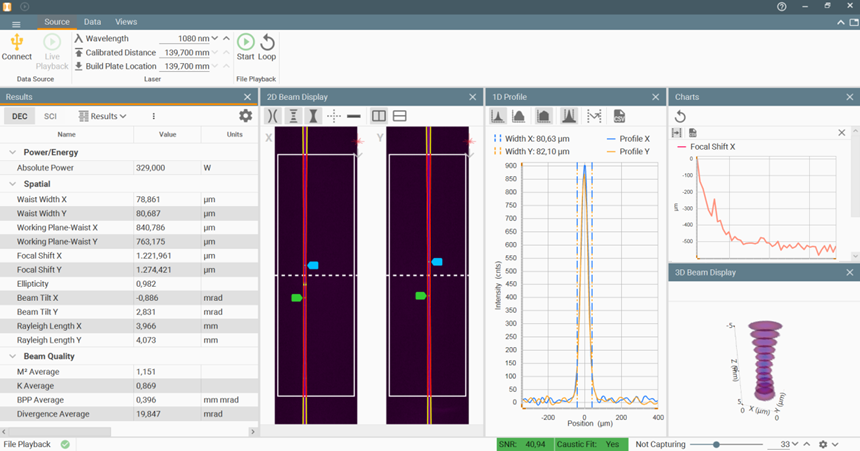

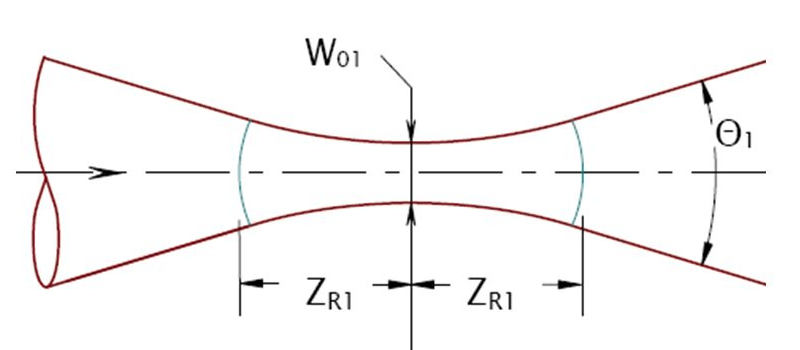

The camera and optical system observe Rayleigh scattering at the beam waist and along the beam propagation in two directions (X and Y). The BeamWatch software then provides real-time, dynamic measurements of multiple beam parameters, including:

- Focus spot size and location

- Focal shift

- M²

- Divergence

- Centroid and tilt angle

This allows users to detect changes during critical moments like laser startup, where focal shift can affect process quality.

High-Power and Power Density Compatibility

The BeamWatch supports lasers from 400 W to unlimited power making it suitable for even the highest power lasers.

The power density within the beam profiling camera’s field of view is not limited by any specific power-per-area threshold. The only limiting factor is the amount of power that the optional power sensor or beam dump can safely handle downstream the beam propagation.

The system includes a GigE interface and software designed for technician-level analysis, featuring tools like Go/No-Go readouts for quick diagnostics. It also supports automation interfaces, enabling integration into industrial workflows.

Choosing the Right BeamWatch® Model for Your Application

Ophir offers several BeamWatch models, each engineered to address the diverse challenges of the high-power laser industry:

The standard BeamWatch, BW-NIR-130, featuring a wide field of view (FOV), is designed to support a broad range of near-infrared (NIR) laser monitoring tasks, including welding, cutting, and cladding.

The BeamWatch Plus, BW-PLUS-45, is designed for advanced, multi-wavelength, high-resolution applications. It offers higher resolution for monitoring smaller focal spots, making it ideal for precision manufacturing. In addition to near-infrared (NIR) lasers, it supports measurements in blue and green wavelengths, enabling accurate profiling for copper welding and other processes where visible high-power lasers are preferred—such as semiconductor processing and medical device fabrication.

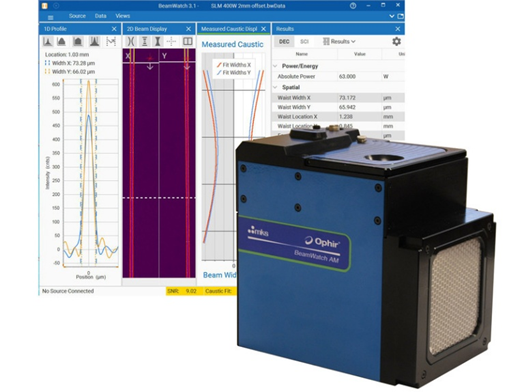

The BeamWatch AM, BW-NIR-2-50-AM, is designed for the demanding environment of additive manufacturing, where timely and accurate analysis of beam performance is critical for maximizing production yield and reducing costs. Built with a compact footprint to fit within various additive manufacturing chambers, it enables in-line measurement of tightly focused beam shapes and focal shifts – essential for precision monitoring in powder-bed fusion and other AM processes to prevent build failures.

To meet the unique requirements of the AM environment, the system includes a pneumatic shutter and overpressure protection to prevent powder contamination. In addition to beam profile monitoring, BeamWatch AM also features an integrated thermal power meter for simultaneous laser power measurement, providing a comprehensive view of laser performance in real time.

The large-scale branch of the BeamWatch family is the BeamWatch Integrated product line. These systems house BeamWatch instrument within a more industrialized platform, incorporating a protective pneumatic shutter, a water-cooled thermal sensor for power monitoring, and an industrial communication computer designed for seamless integration into factory control systems via PROFINET or EtherNet/IP protocols.

BeamWatch Integrated is built as a component of automated manufacturing and welding production lines, particularly in the automotive sector where high-power lasers are commonly used. It provides simultaneous real-time measurement of all critical laser beam parameters, while its built-in power meter delivers absolute power readings. The pneumatic shutter protects the optics from dust and debris in harsh industrial environments, and the integrated flowmeter monitors the cooling efficiency of the power sensor to ensure stable operation.

Comparison Between Different BeamWatch models:

| Feature | BeamWatch | BeamWatch Plus | BeamWatch AM | BeamWatch Integrated |

| Use Case | General high-power lasers | High-resolution, multi-wavelength | Additive manufacturing | Automated production lines |

| Min Spot Size (µm) | 130 | 45 | 50 | 50/150 |

| Spectral Range (nm) | 950–1100 | 420–635 / 950–1100 | 1060–1080 | 980–1080 |

| Power Range | 400 W to unlimited | NIR: 400 W to unlimited VIS: 3 W to >100 kW | 50–1000 W | 500 W to 10kW (up to 30kW upon demand) |

| Power Measurement | No | No | Yes (NIST-traceable) | Yes (NIST-traceable) |

| Automation/Integration | Manual | Manual | Semi-integrated | Fully automated |

| Industrial Interfaces | No | No | No | PROFINET, Ethernet/IP, CC-Link |

| FOV | 26 × 9 mm | 9 × 3 mm | 9 × 3 mm | 32 × 9 mm |

| FOV Resolution | 16.5 µm | 5.5 µm | 5.5 µm | 16.5 µm |

| Max Beam Diameter | 12.5 mm | 12.5 mm | 8 mm | 12.5 mm |

| Typical Applications | Laser welding, cutting, maintenance | Precision manufacturing, medical devices, semiconductors | Metal 3D printing, powder-bed fusion, aerospace AM | Automotive welding, robotic systems, inline QC |

Still not sure which BeamWatch fits your process?

Contact us for tailored guidance.

Leave a Reply

Your email address will not be published. Required fields are marked *