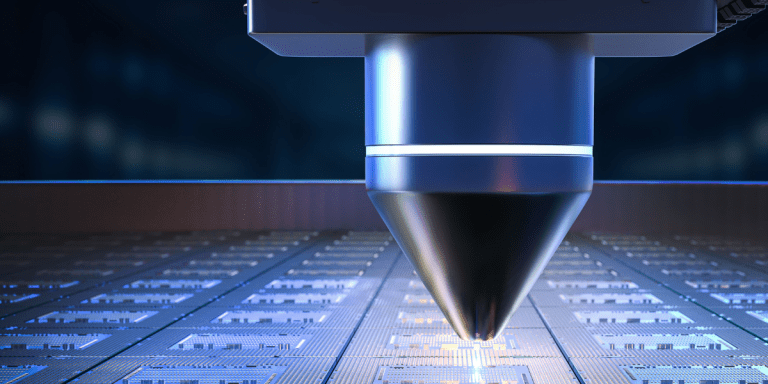

In the rapidly evolving world of laser applications in microelectronics packaging, precision and reliability are paramount. The name of the game is HAZ (or Heat Affected Zone), and the goal is to develop processes that maximize energy absorption where it is needed and minimize the HAZ. Accurate power measurement becomes critical for ensuring the effectiveness of these laser processes, and that’s where Ophir’s laser power meters come into play.

Let’s look at some of these laser processes:

- 5G Antenna Cutting and Drilling: Flexible wireless antennas are made of composites of materials with very different thermal properties such as copper and polyimide. Nanosecond and picosecond lasers are used to cut and drill multilayer composites without damaging heat-sensitive layers.

- Optical Debonding: Used, for example, for separating OLED displays from a glass support. Ultraviolet and visible nanosecond lasers are used for separation of devices from temporary carriers without creating mechanical strain which can lead to cracks.

- Micro-via Drilling: The demand for smaller and more densely packed micro-via’s is driving the industry to transition from the well-established CO2 laser to nano and pico second UV lasers, reducing the HAZ and allowing for small diameter via’s.

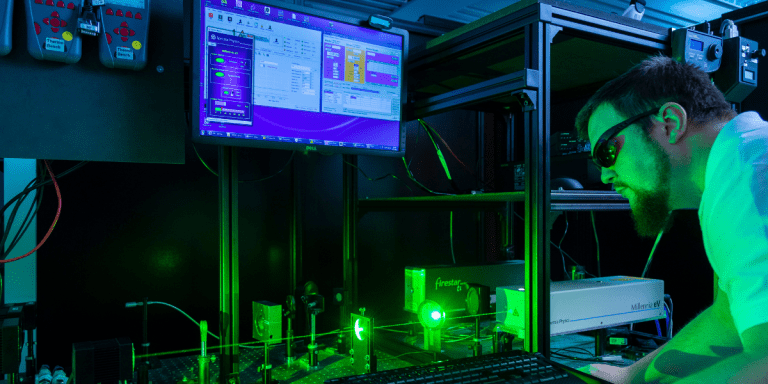

For these applications to be successful, the power of the lasers must be precisely measured and controlled. Inaccurate measurements can lead to suboptimal processing and reduced yields.

The challenge in achieving accurate and reliable measurements with ultra-short pulse lasers lies in their ability to evaporate and cut through many materials. This makes it difficult to find materials and coatings for the power meter that can effectively absorb the laser without damaging.

Additionally, components such as lenses, diffusers, or beam splitters, which may be used to reduce the power on the power meter, can also be damaged or contaminated by the ultrashort pulses especially in the UV, leading to skewed measurements.

Ophir’s product portfolio offers some dedicated solutions for these laser applications:

The ‘CM’ and ‘SV’ absorbers represent some of the toughest materials available and can be used for nanosecond, picosecond and even femtosecond lasers.

Conclusion

In the world of advanced packaging, Ophir’s laser power meters provide the accuracy, reliability, and versatility needed to ensure that laser-based processes are optimized for maximum efficiency and yield. By choosing Ophir, manufacturers can be confident that they are using the best tools available to measure and control their laser systems.