As the laser and Photonics industry enters 2026 amid rapid advances in power, speed, and production demands, we sat down with Reuven Silverman, General Manager MKS Ophir Photonics Products, to reflect on the past year and look ahead.

In this conversation, Reuven shares how 2025 reshaped laser measurement requirements across semiconductor, industrial, and defense markets, and how MKS is positioning itself for the next phase of growth, as laser measurement moves deeper into production environments.

Looking back, how would you summarize 2025 for the MKS Ophir photonics product line?

2025 was the year Ophir photonics products made ultra-high-power and ultrafast laser measurement simpler, faster, and more production-ready, bringing lab-grade accuracy out of the lab and into harsh semiconductor, industrial and defense environments.

This was enabled by major launches such as the 70 kW Power-from-Pulse™ sensor as well as the BeamSquared Pro M² measurement device.

What do you see as the most meaningful milestone this year?

The most meaningful milestone this year was expanding our Power-from-Pulse™ measurement capability on the Ophir 70 kW sensor to accurately measure CW power up to 100 kW.

This advancement enables reliable derivation of continuous-wave power from short, high-energy laser exposures typical of directed-energy systems and high-power test stands, applications where tools operating at 120–150 kW were previously used mainly as beam dumps rather than true measurement systems.

Previously, achieving accurate results required lasers to run for 30–40 seconds. With the Power-from-Pulse™ feature, accurate measurements can now be achieved in just a few seconds, dramatically improving test efficiency.

By combining precise power sensing and beam dumping in a single unit, the enhanced sensor materially reduces test complexity, improves safety with less than 0.5% back-reflection, a critical factor when operating at extreme power levels, and significantly shortens qualification cycles for high-energy laser platforms.

Which customer application segments changed the most in 2025?

The biggest shifts were seen across semiconductor micromachining, high-power industrial manufacturing and defense.

In semiconductor and electronics micromachining, rapid growth in micro-processing and increasingly tight tolerances significantly increased demand for highly accurate beam caustic and M² (beam quality) characterization directly in production, which we addressed with the BeamSquared SP204S-PRO.

In additive manufacturing and industrial welding and cutting, the adoption of higher-kilowatt fiber lasers, along with growing use of blue and green wavelengths, introduced new measurement challenges. These applications require robust, easy-to-integrate sensors capable of handling higher power levels across a broader spectral range, pushing us beyond traditional near-infrared measurement regimes.

In defense and directed-energy applications, the move toward short-duration, high-burst exposures created a need to measure power from pulses rather than relying solely on steady-state methods, directly driving the enhancement of our 70 kW Power-from-Pulse™ platform.

What major industry trends stood out in the laser and photonics world in 2025?

One of the clearest trends in 2025 was the strength of micro-processing relative to macro markets, driven by semiconductors, advanced packaging, and display technologies.

At the same time, ultrafast lasers continue to gain momentum, with multiple industry forecasts predicting double-digit growth in picosecond and femtosecond sources through 2030 as precision manufacturing scales.

Despite broader economic headwinds, the laser market has remained resilient, with continued expansion across communications, automotive LiDAR, defense, and medical applications.

Finally, policy and tariffs became a real industry factor in 2025, as new tariffs on critical photonics components rippled through global supply chains and extended lead times.

How did geopolitics, supply chains, and sustainability impact the industry?

Supply-chain re-routing and cost pressure from evolving tariffs forced customers to localize component qualifications and build redundancy into their vendor base. This increased demand for faster calibration turnarounds and drop-in replacements for measurement equipment.

At the same time, sustainability and uptime have become operational priorities. Factories running 24/7 require measurement tools that integrate digitally, support predictive maintenance, reduce scrap through closed-loop control, and survive continuous production environments, areas where MKS is particularly well positioned.

Where will AI, automation, and data-driven workflows have the biggest impact?

AI and automation will have an immediate impact across how measurement systems are developed, how they operate, and how customers use their data.

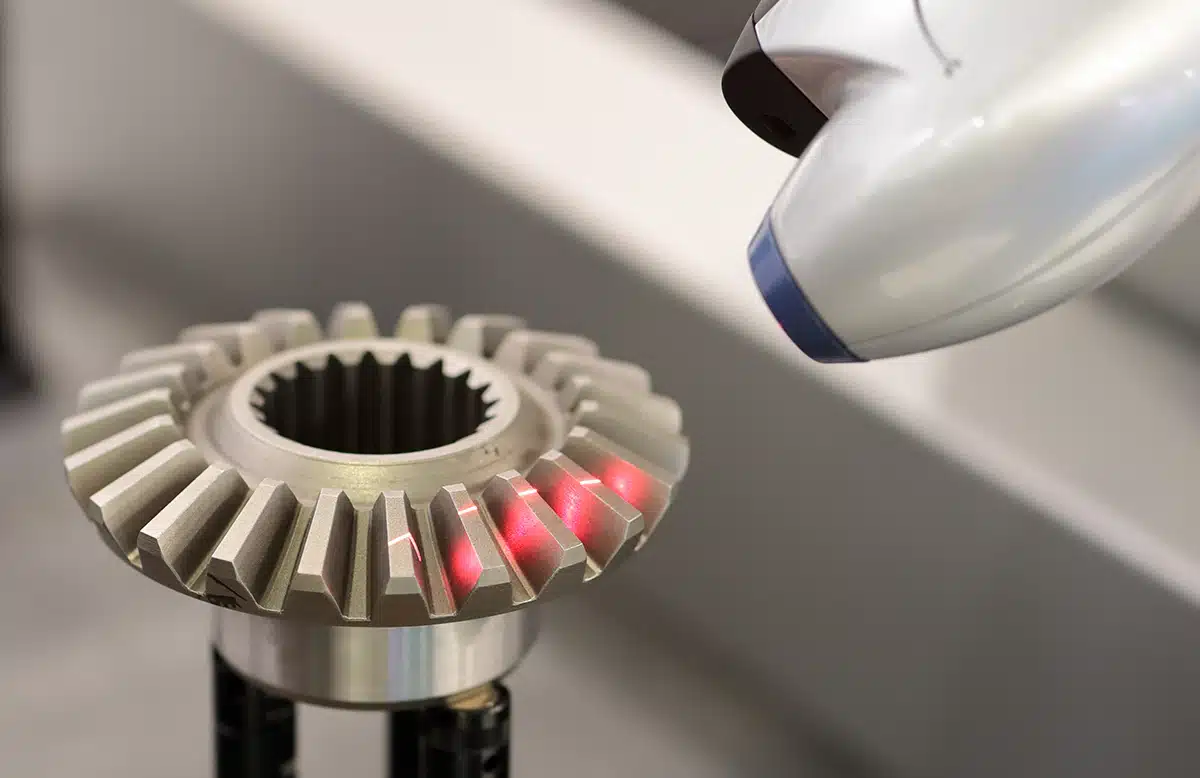

On the factory floor, automated beam characterization and inline power verification enable standardized, hands-off routines that feed SPC (Statistical Process Control) and process-control systems.

From a systems perspective, expanded data availability, Ethernet and RS-232 connectivity, and real-time outputs simplify integration with MES (manufacturing execution) platforms, allowing customers to apply their own analytics or AI tools to optimize yield and consistency.

How are Ophir sensors and profilers evolving to meet new demands?

We’re advancing along three parallel paths: robustness, accuracy, and ease of use.

For high-power robustness, this includes larger apertures, ultra-low back-reflection, integrated beam dumps, and water-cooled calorimetric systems such as the 70 kW Power-from-Pulse™ platform.

For ultrafast accuracy, BeamSquared systems now support longer optical trains, reduced system-to-system variation, and higher-precision M² measurements – critical for femtosecond and picosecond process windows.

Finally, ease of use is driven by automation, ISO-11146 beam characterization compliance, and camera and software upgrades that reduce setup time and operator variability.

Where is the MKS Ophir photonics product line most clearly differentiated today?

The clearest differentiation is our ability to combine deep expertise in both power measurement and beam profiling.

Very few companies can do both at a high level, and even fewer can integrate them into production-ready systems. With over 2,000 catalog items, integrated safety features, and digital connectivity, we offer one of the broadest and most flexible measurement portfolios in the industry.

As we often say: if you have a laser, we can measure it.

Where is the most innovation happening inside the Ophir photonics product line today?

Innovation is strongest in production-grade beam propagation systems and in scaling our sensor portfolio for higher-power classes.

Platforms like BeamSquared SP204S-PRO/SP1203 bridge metrology-level rigor with shop-floor practicality, while new sensors spanning 20 kW up to 150 kW address the market’s steady climb in laser power.

Can you share an example where improved measurement data boosted yield or throughput?

We’ve seen particularly strong adoption of Helios Pro for inline power monitoring in high-duty-cycle environments.

Customers using Helios Pro have been able to close the loop between measurement and process control, stabilizing output in multi-shift production lines. The fact that customers continue ordering the system for new lines is a strong indicator of its impact on yield and consistency.

Entering 2026, which areas will grow in importance?

Looking into 2026, three areas stand out: inline connected metrology for micro-processing applications, resilient regional supply chains, and continued scaling of kilowatt-class measurement with built-in safety.

With SPIE Photonics West exhibition as our most important annual milestone, we’ll be introducing a wide range of new products and technologies early in the year that directly address these needs.

Looking five years ahead, how will laser measurement evolve?

Laser measurement is moving from standalone tools to embedded, automated, data-driven platforms.

Systems must drop seamlessly into production, deliver real-time alerts, and support analytics-driven optimization. At the same time, higher powers and broader wavelength ranges, from UV through visible wavelengths such as blue and green, will continue to emerge across defense, medical, and industrial markets.

A long-term focus is to lead in production-grade accuracy: delivering plug-in, connected, ISO-compliant measurement solutions that are robust enough for lights-out factories and field test ranges, while shortening time-to-qualification for the next generation of laser platforms.

Looking ahead, the themes are clear: laser measurement is becoming more embedded, more automated, and more tightly integrated into production environments. As laser systems continue to scale in power, speed, and wavelength diversity, MKS’ focus on production-grade accuracy, safety, and connectivity positions it to support both today’s factories and tomorrow’s emerging applications.

These are exciting times for the laser industry, and we’re looking forward to helping shape what comes next.