Introduction: The Evolution of PCB Drilling

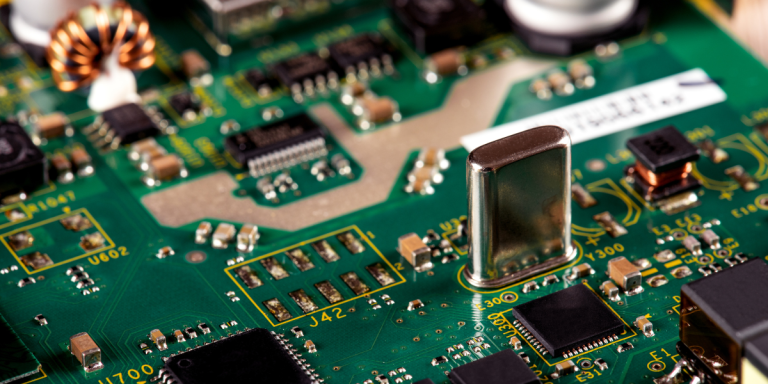

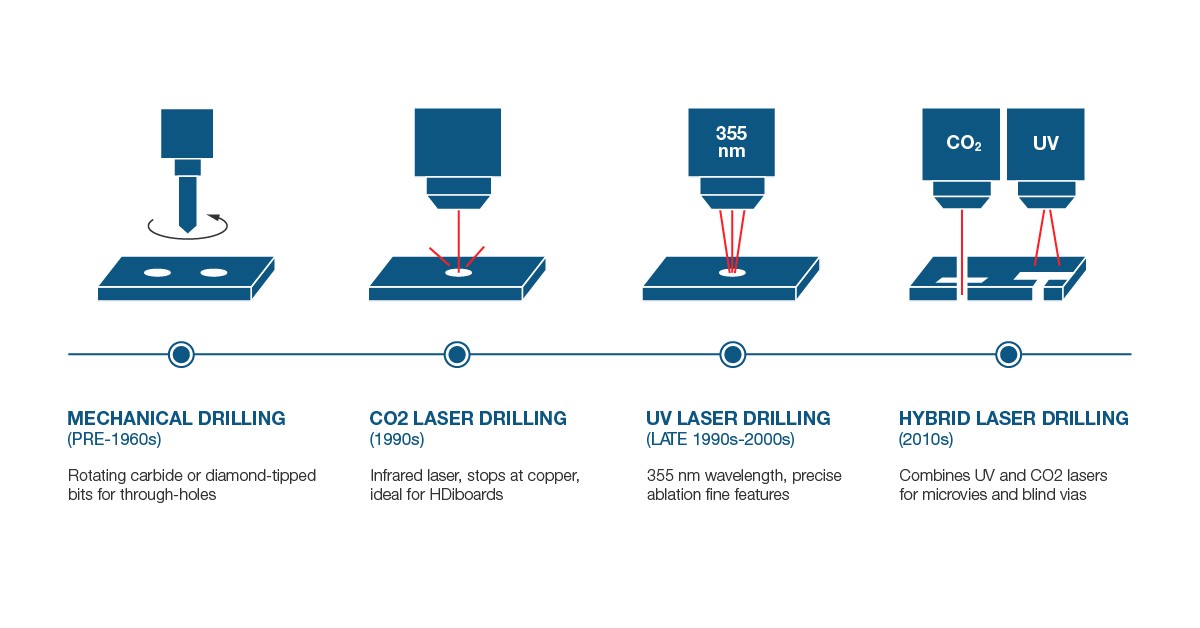

The evolution of PCB drilling technology has progressed significantly over the decades, beginning with mechanical drilling, which has been in use since before the 1960s. This method relies on rotating carbide or diamond-tipped drill bits to create through-holes in single- and double-sided boards. While effective for basic layouts, mechanical drilling suffers from limitations in precision, tool wear, and the inability to control drilling depth automatically. As the electronics industry moved toward multilayer and compact designs, the need for more accurate and efficient drilling methods became critical.

From CO₂ to UV: A Shift in Laser Precision

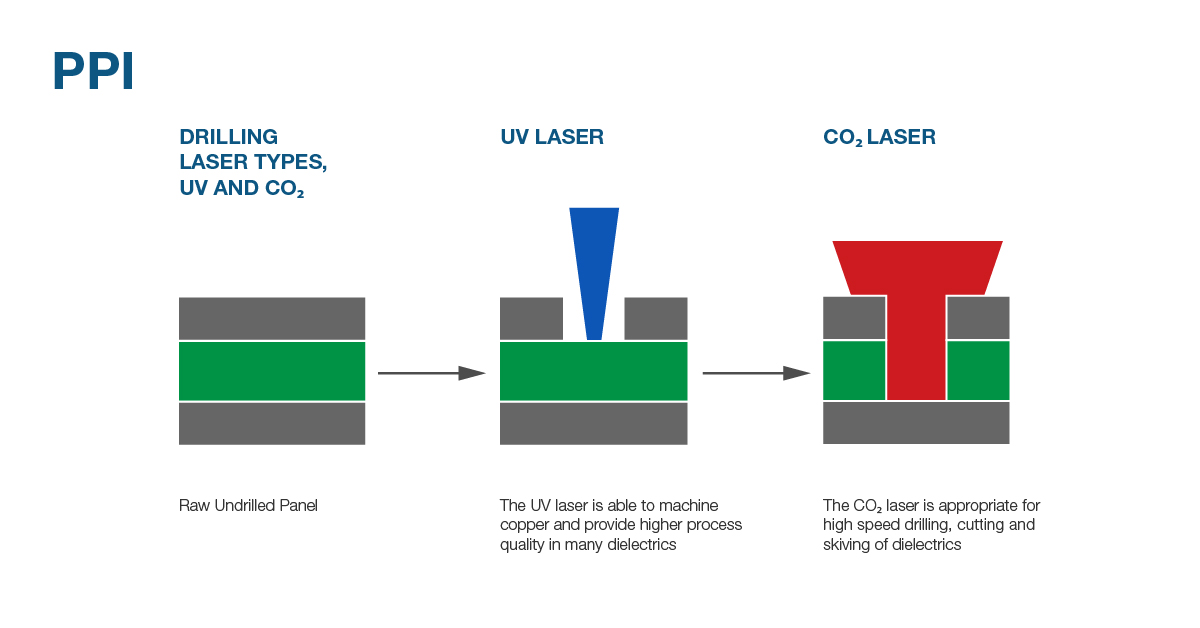

In the 1990s (Figure 1), CO₂ laser drilling emerged as a transformative solution. Operating at an infrared wavelength of approximately 9.4 µm, CO₂ lasers offered high energy density for rapid dielectric removal. A key advantage was their interaction with copper: due to copper’s high reflectivity in the infrared spectrum, the laser beam naturally stopped at copper layers, enabling precise microvia formation without over-penetration. This made CO₂ lasers ideal for HDI boards, where controlled depth and high throughput were essential. However, as feature sizes continued to shrink, even finer control was needed.

By the late 1990s and early 2000s, UV nanosecond lasers, typically operating at 355 nm, were introduced to meet the demand for smaller vias and finer geometries. These lasers provided high absorption in both copper and organic materials, allowing for precise ablation with minimal thermal damage. However, they lacked the natural stop-at-copper behavior of CO₂ lasers, requiring more sophisticated process control. This led to the development of hybrid laser drilling systems in the 2010s, combining UV and CO₂ lasers. In this approach, the UV laser drills through the top copper and dielectric layers, while the CO₂ laser completes the via by removing the remaining dielectric and stopping at the next copper layer (Figure 2). This hybrid method delivers both the precision and throughput needed for today’s advanced multilayer PCB designs.

The following table summarizes how each laser technology enables specific PCB features:

To better understand how laser drilling supports these applications, the table below summarizes key features, the laser technologies that enable them, and their specific benefits in PCB manufacturing:

| Feature | Enabled By | Benefit |

| Microvias | UV/CO₂ lasers | High-density routing in HDI boards |

| Blind/Buried Vias | Hybrid laser drilling | Compact multilayer designs |

| Controlled Depth | CO₂ laser reflectivity | Natural stop at copper layers |

| Fine Feature Resolution | UV lasers (355 nm) | Precision in small geometries |

| Material Versatility | Multi-wavelength lasers | Compatibility with FR4, polyimide, PTFE, and other substrates |

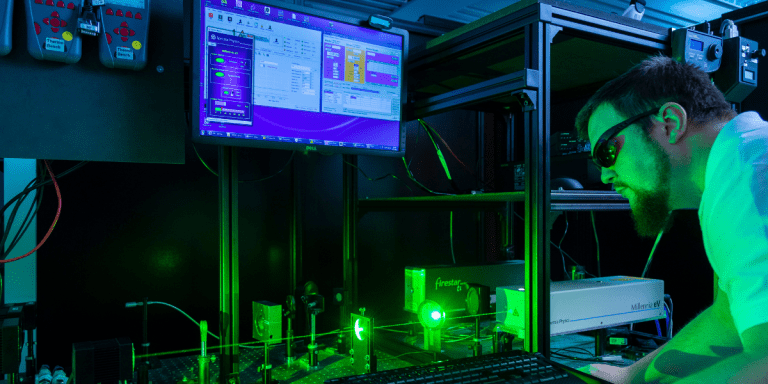

Pyrocam: PCB process diagnostic

As laser-based processes like Laser Lift-Off (LLO) and hybrid drilling become central to advanced PCB manufacturing, maintaining beam quality, energy distribution, and spatial uniformity is critical. This is where Pyrocam, a high-resolution pyroelectric array camera, becomes indispensable. Designed to capture and analyze laser beams across UV to IR wavelengths, Pyrocam is uniquely suited for multi-wavelength systems used in PCB fabrication.

In LLO applications, used to delaminate thin films like polyimide from carrier substrates, Pyrocam ensures uniform energy delivery by visualizing the beam profile in real time. This prevents incomplete lift-off, substrate warping, or thermal damage. In UV and CO₂ laser drilling, Pyrocam supports beam alignment, focus optimization, and mode stability, which are essential for producing clean, high-aspect-ratio microvias and controlled-depth blind vias. For hybrid drilling, Pyrocam enables dual-beam diagnostics, allowing engineers to independently monitor both laser sources and ensure optimal performance throughout the drilling sequence.

As PCB designs grow increasingly complex, the role of laser technologies has shifted from optional enhancement to essential infrastructure. Tools like Pyrocam are no longer just diagnostic aids, they are integral to maintaining process integrity across UV, CO₂, and hybrid laser systems. By enabling real-time beam profiling, alignment verification, and closed-loop control, Pyrocam supports consistent via quality, minimizes defects, and ensures repeatable performance in high-volume production. In advanced packaging and HDI environments, this translates into tighter tolerances, higher yields, key metrics for any manufacturer pushing the limits of electronic miniaturization.