Why Laser Measurement Matters

As laser technology continues to advance at an incredible pace, maintaining precise and consistent laser performance has never been more critical. In industrial materials processing, even small variations in beam characteristics can lead to reduced efficiency, lower product quality, or costly downtime.

This post outlines best practices for measuring, analyzing, and maintaining laser system performance, helping engineers and technicians get the most out of their lasers and avoid common pitfalls.

Power Density: The Core Metric

Whatever the application, cutting, welding, additive manufacturing, or marking, it’s essential to understand how the laser interacts with the target material.

That interaction is largely defined by power density (W/cm²), determined by two key parameters:

1. Laser Output Power or Energy

The total amount of laser light delivered to the material.

- For CW lasers, this is measured as continuous power.

- For pulsed lasers, average power or energy per pulse (and thus energy density) is measured.

2. Focused Spot Diameter

The area over which the laser power is distributed.

Any change in either of these parameters affects how the material absorbs energy.

For example, dirty mirrors or degraded optics can reduce power, shift focus, or distort the beam, all of which alter the process outcome.

Regular on-site measurement ensures the laser is operating as designed.

Challenges of High-Power Lasers

Measuring high-power lasers poses unique challenges. Safety risks to eyes and skin increase, and the measurement hardware itself can be stressed by intense power levels.

Even as OEMs improve efficiency and reliability, every optical component; mirrors, lenses, fibers, ages and eventually degrades. When performance drops, simply turning up the power only masks the problem and accelerates wear.

Routine measurement and preventive maintenance save both time and cost by identifying degradation early.

Key Laser Characteristics to Measure

Power alone doesn’t tell the full story. Comprehensive laser performance analysis should include:

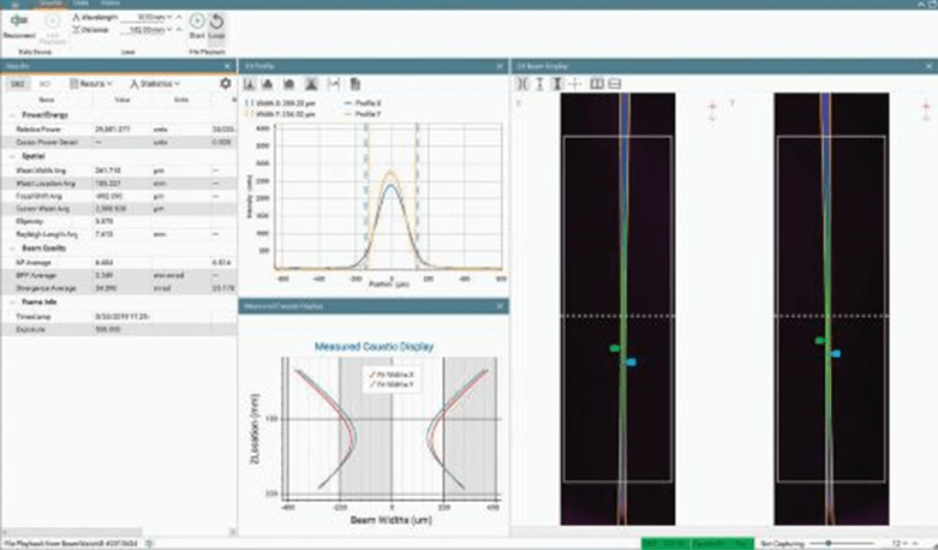

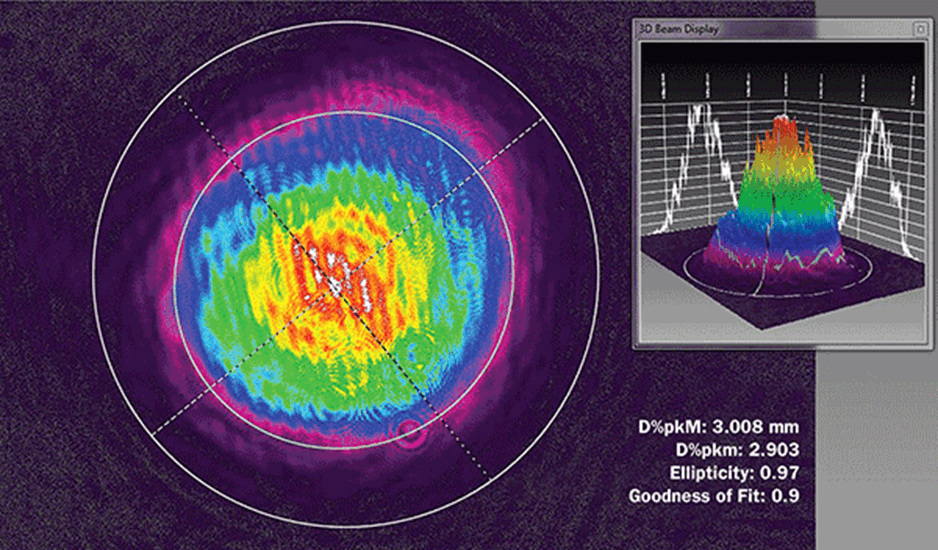

- Beam profile and shape – energy distribution and symmetry.

- Ellipticity, Gaussian or Top-Hat fit – indicate beam quality and uniformity.

- Beam Propagation Ratio (M²) or Beam Parameter Product (BPP) – show how the beam focuses and diverges.

- Focused spot location over time – detects thermal drift or misalignment.

- Pulse duration and pulse shape (for pulsed lasers) – monitor the consistency of pulse generation and timing.

Monitoring these parameters over time enables early detection of alignment drift, contamination, or component wear before production quality suffers.

Performance Measurement Techniques

1. Thermopile “Power Pucks”

Still widely used, these provide a quick snapshot of laser power. However, they lack long-term trending and can miss fluctuations over time.

2. Electronic Power Measurement

Modern fan or water-cooled thermopile sensors, connected to a meter or PC interface, collect continuous data over minutes or hours.

This enables trend analysis and predictive maintenance — for instance:

- A consistent 10–15% drop may signal dirty optics.

- A rapid power drop suggests a damaged mirror or lens.

- Erratic readings may point to an unstable source or power supply issue.

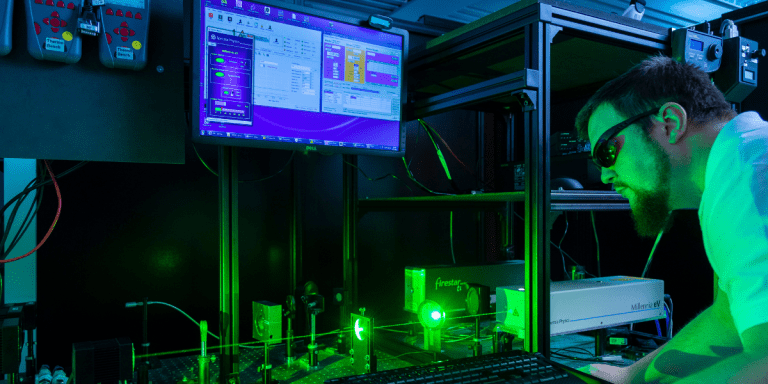

3. Beam Profiling

Legacy tools like burn paper or acrylic blocks give only a static snapshot.

Modern camera-based or scanning-slit profilers provide precise, repeatable, and time-resolved beam data, including beam size, symmetry, and position.

They also enable objective, standards-based analysis rather than subjective interpretation.

For high-power 1-µm lasers, non-contact beam profiling systems now allow safe, real-time visualization of the focused spot without risk of damage.

In-Process vs. At-Process Measurement

Two complementary approaches are used in modern production:

In-Process Measurement

A permanently integrated sampling system that monitors a fraction of the beam in real time.

Enables closed-loop feedback.

Doesn’t analyze the full optical path, so downstream issues can go undetected.

At-Process Measurement

The entire beam is analyzed at the worksite using power, energy, and beam-profiling tools.

Captures complete system performance.

Requires temporary production downtime for setup.

Combining both methods gives the most complete view of laser health and process stability.

Turning Data into Action

Regular measurement and trending establish a performance baseline, a benchmark for comparison.

If system components later degrade, that benchmark provides a known “good” reference for troubleshooting and calibration.

Modern integrated systems can even send automated alerts to maintenance teams or PLCs when deviations exceed preset thresholds, allowing proactive action before quality or uptime are affected.

Key Takeaways

- Measure both power and beam size regularly — power alone isn’t enough.

- Keep optics clean and monitor thermal drift to maintain consistent focus.

- Use electronic, camera-based, or non-contact systems for accurate, repeatable results.

- Combine in-process and at-process monitoring for full coverage.

- Trend your data over time to detect problems early and benchmark performance.

Conclusion

Understanding how your laser performs shouldn’t be a guessing game.

With the right measurement tools and disciplined best practices, engineers can optimize productivity, improve quality, and extend laser system life.