As heavy industry continues to rely on cutting-edge technologies to drive efficiency and precision, lasers have become essential tools. From cutting and welding to surface treatment and quality control, lasers bring a host of advantages to various industrial applications. However, to achieve optimal results and maintain consistent quality, accurate laser measurement is crucial. Proper laser measurement ensures that the laser operates correctly with specified power levels for each specific task, whether it’s cutting metal, drilling plastic, or any other material processing.

This post explores the role of laser measurement in heavy industry, covering applications, benefits, challenges, and future trends.

Industrial Lasers and Role of Measurement

Industrial lasers are powerful, precise tools used for specific applications in heavy industry. Different types of industrial lasers, such as CO2, fiber and diode lasers are used in different applications based on their strengths and suitability for particular tasks.

- CO₂ Lasers: Known for their ability to cut various materials, including metals, plastics, and glass. Power or energy measurement here ensure that the laser maintains the right intensity for smooth, clean cuts without overheating or damaging the material.

- Fiber Lasers: These solid-state lasers are ideal for metal processing and are widely used in automotive and aerospace industries. It is obvious that without precise measurement of laser parameters it is impossible to ensure process quality and there is a potential risk of deformation and weakening of the materials.

- Diode Lasers: Diode lasers are used in lighter applications, like marking or engraving. Measurement is necessary to keep laser power within a controlled range, preventing surface scorching, and ensuring uniform and high-quality finish.

Key Lasers Applications in Heavy Industry

- Laser Cutting: To achieve clean and precise laser cutting, power and energy measurement is critical. Ensuring consistent laser performance prevents cutting variations, uneven edges, and wasted material. Laser measurement systems allow operators to fine-tune the beam for each material, ensuring it penetrates precisely at the intended depth without compromising speed or finish quality.

- Laser Welding: In critical sectors like automotive and aerospace, laser welding demands high consistency and strength in welds. By measuring critical laser parameters, operators (or automatic control system) can ensure that the laser beam is sufficient for creating robust joins without overheating and deforming parts. Maintaining correct power levels also improves weld longevity and reduces the likelihood of material fatigue.

- Laser Drilling: Precision drilling requires a very controlled laser beam to create clean, accurate holes, especially in industries such as aerospace, where even small imperfections can lead to performance issues. Accurate power measurement ensures that the laser’s energy is maintained at the optimal level for each drilling task, preventing the laser from burning or cracking the material.

- Surface Treatment and Engraving: For applications like engraving or surface texturing, consistent laser power and energy are essential to achieving uniform patterns and finishes. Power measurement prevents the laser from creating irregular textures, ensuring that each design is consistent and aesthetically pleasing.

- Measurement and Quality Control: Lasers used for scanning or quality assurance require precise energy control to prevent overheating and maintain measurement accuracy. Ensuring stable power allows these lasers to operate efficiently and extend their life span, reducing the frequency of maintenance.

Advantages of Accurate Measurement in Laser Apps.

- Precision and Accuracy: Proper laser measurement allows for exact calibration, enabling precise results in cutting, drilling, and welding. This accuracy is crucial for industries where even minor deviations can lead to product failures.

- Efficiency and Speed: Accurate power control leads to faster processing and higher throughput. By maintaining the correct power levels, lasers can operate at maximum efficiency without risking material damage, allowing manufacturers to maintain high production speeds.

- Material Versatility: With precise measurement, lasers can be adjusted for a range of materials, from metals to plastics, with specific settings optimized for each type. This flexibility ensures that materials are not overheated or undercut, improving product quality across different applications.

- Reduced Waste and Environmental Impact: Accurate measurement minimizes errors and waste, helping to reduce the environmental impact of manufacturing processes. By optimizing power use, industries can also reduce their energy consumption, contributing to more sustainable operations.

Challenges and Limitations of Laser Use in Heavy Industry

- Initial Cost and Maintenance: Industrial lasers and measurement tools can be expensive to purchase and maintain. While they offer long-term savings, initial costs can be prohibitive for smaller operations.

- Safety Considerations: Lasers require strict safety protocols, especially as power levels increase. Proper measurement and control help mitigate risks, but operators still need rigorous training to handle high-powered lasers safely.

- Material Limitations: Some materials are less responsive to laser processing, even with precise power control. In these cases, specialized settings or alternative methods may be necessary.

- Energy Consumption: Power and energy measurement play an important role in managing energy consumption. However, heavy-duty lasers still require significant energy, leading to higher operational costs.

Future Trends in Laser Technology for Heavy Industry

- Advances in Laser Power and Precision: As laser technology evolves, new systems are being developed that offer greater power control, enabling manufacturers to work with even greater precision on harder materials.

- Automation and AI Integration: Combining laser systems with AI and automation is paving the way for real-time adjustments based on measurement feedback. This integration will allow for highly controlled, automated laser operations that can self-adjust for optimal energy use and power levels.

- Green Lasers and Energy Efficiency: Researchers are working on more energy-efficient laser systems that can maintain power without excessive consumption. These advancements will help reduce operational costs while ensuring sustainable practices.

- Expanding Applications: New laser applications are emerging, such as laser-based additive manufacturing, where measurement is essential to ensure each layer of material is deposited accurately. This trend highlights the growing importance of precise measurement for innovative applications in industry.

Conclusion

Lasers have revolutionized heavy industry with their precision, speed, and versatility. Yet, achieving these benefits hinges on accurate laser power and energy measurement. By ensuring that lasers operate at optimal levels, manufacturers can reduce waste, enhance product quality, and maintain efficient processes. As laser technology continues to advance, the importance of accurate measurement will only grow, helping industries achieve smarter, safer, and more sustainable manufacturing solutions.

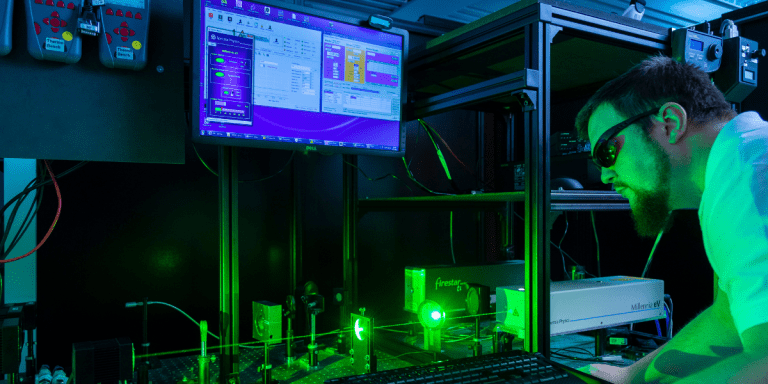

Our Laser Measurement Solutions

At MKS, we understand that accurate laser power and energy measurement is essential for the success of any industrial application. Through our Ophir® photonics product line, we offer a comprehensive portfolio of measurement equipment designed for different types of applications and for different material processes. Our product lines cover standard (catalog) products for common industrial needs, as well as customized solutions tailored to a specific customer requirements. We consider all aspects of the requirements including mechanical, communication, cooling and others.

Our equipment enables customers to achieve optimum laser performance by ensuring precision, safety and efficiency in all applications.

For more information, feel free to contact us and we will help you power your success.