The Measurement Challenge Behind Modern Beam Shaping

As advanced laser technologies continue to influence industrial welding and additive manufacturing, the need for accurate and application‑specific beam characterization remains important.

In laser welding, a Ring‑Core shaped beam can help reduce spatter, support stable operation, and improve energy distribution, contributing to cleaner and more consistent processing.

In Additive Manufacturing the use of Ring/Core beam shaping systems is also expanding. Adjustable ring and core profiles allow real‑time tuning of the laser shape to balance precision and throughput while lowering spatter levels, which can support cleaner builds and more efficient fusion.

Ophir’s Ring/Core BeamGage software addresses these needs. Recently announced by MKS, it is the first commercial software developed specifically for characterizing Ring/Core‑shaped laser beams, providing measurement capabilities relevant to high‑power welding, additive manufacturing, and materials processing.

A Purpose-Built Solution for Ring/Core Beam Analysis

Rather than adapting traditional profiling workflows, Ring/Core BeamGage introduces analysis models developed specifically for ring-and-core beam geometries. Ophir’s new Ring/Core BeamGage software changes that. Officially announced by MKS, this is the first commercial software designed specifically for characterizing Ring/Core‑shaped laser beams, delivering new measurement capabilities vital for high‑power welding, additive manufacturing, and advanced materials processing.

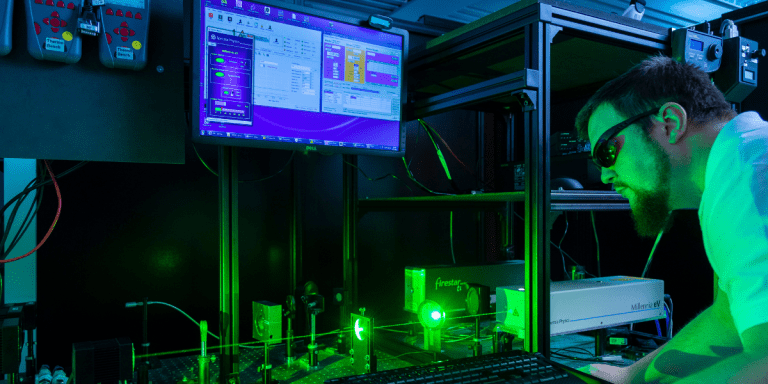

Designed for High-Power Profiling Platforms

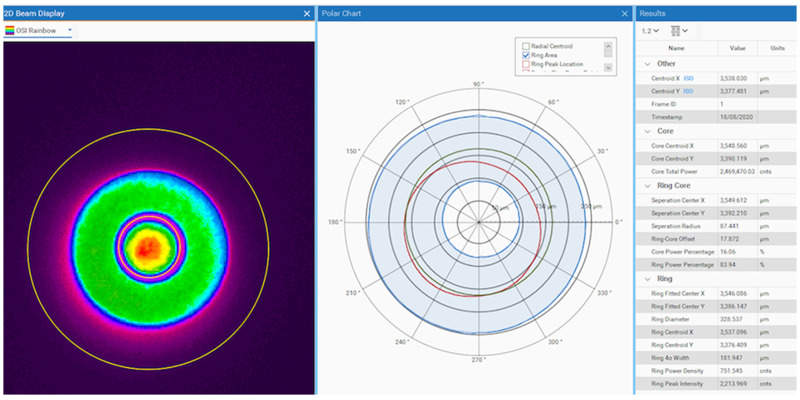

Compatible with Ophir profilers such as the SP204S, SP932U, and SP402S, the software performs real‑time analysis of ring and core regions. These features align with the increasing adoption of Ring‑Core laser systems across the industry and provides metrics including:

- Ring‑to‑core offset

- Ring/Core power ratio

- Ring/Core gap size

- Ring/Core diameters and centroids

- Polar charts to support alignment tasks.

These platforms are widely deployed in high-power industrial environments where accurate beam characterization must be performed safely and without disrupting production workflows.

As beam-shaping technologies move from R&D into mainstream production systems, these capabilities directly support the rapid adoption of C/R laser systems from leading global laser manufacturers.

Supporting Additive Manufacturing Process Control

These dynamic beam profiles create new process monitoring and validation requirements throughout the build cycle. The emergence of C/R beam shaping in AM systems from industry leaders introduces dynamic beam control during the fusion process. Adjustable ring/core profiles allow:

- Real‑time optimization of melt‑pool shape and surface finish

- A tunable balance between precision and production speed

- Reduction of spatter, resulting in cleaner builds

- Faster fusion rates and support for higher‑power C/R configurations

Characterizing these beams at industrial power levels also introduces safety and sensor survivability considerations, further underscoring the need for purpose-built profiling solutions.

By providing dedicated tools for analyzing ring-and-core beam structures, the platform supports more accurate system alignment, improved process validation, and faster adoption of advanced beam-shaping technologies.

Availability and Demo Access

Currently available for beta evaluation or demo, Ring/Core BeamGage offers laser manufacturers, integrators, and advanced production teams the measurement framework needed to characterize next‑generation beam shapes safely and confidently. Organizations evaluating Ring/Core laser systems can request beta access or a guided demonstration to explore the software’s measurement capabilities in real-world applications. Demo access and camera licenses are available through service.ophir.il@mksinst.com.

Official press release: https://www.mks.com/pr-ophir-ring-core-beamgage-software-20260121