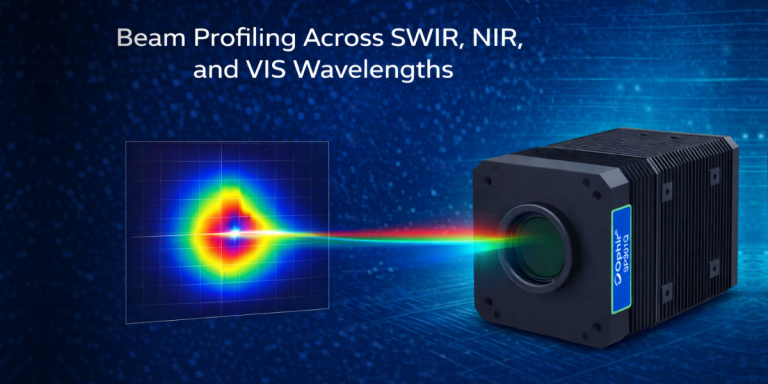

Cost-Effective, High-Performance Beam Characterization from Visible to SWIR

Accurate laser beam characterization is essential across a growing range of photonics applications, from LiDAR and face recognition to optical communications to military systems. Yet for many engineers and system integrators, accessing high-quality shortwave infrared (SWIR) beam profiling has traditionally required expensive, export-controlled camera technologies.

To address this gap, MKS Inc. has introduced the Ophir® SP301Q Colloidal Quantum Dot (CQD) Beam Profiler, a next-generation solution designed to deliver high performance across visible, NIR, and SWIR wavelengths in a more accessible and cost-effective platform.

Expanding Access to SWIR Beam Profiling

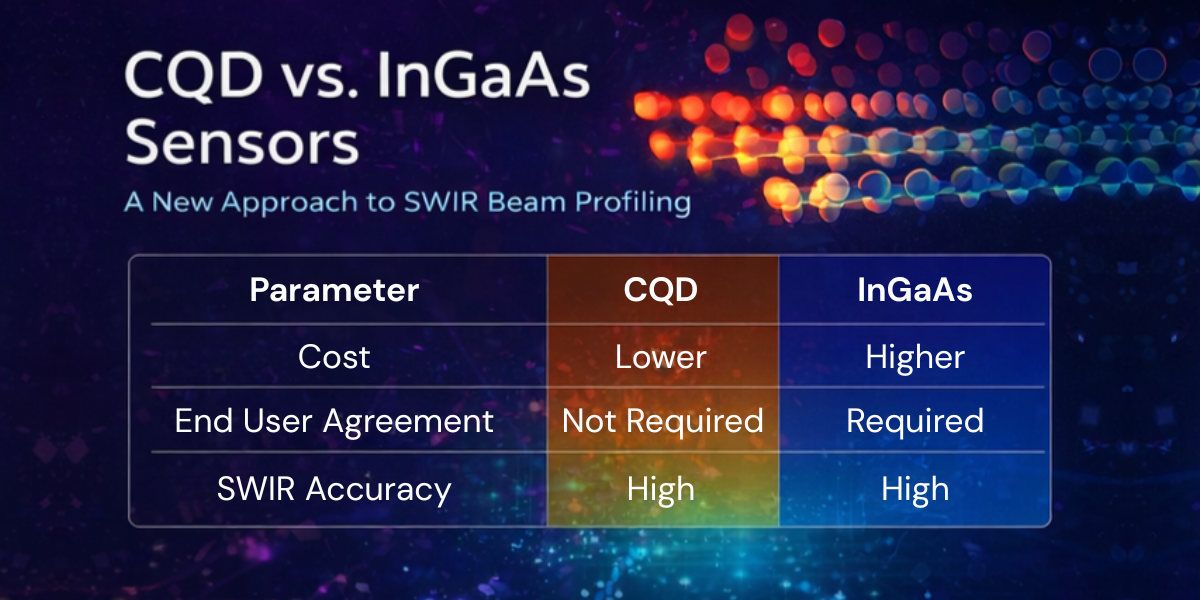

Conventional SWIR beam characterization often relies on InGaAs camera sensors, technologies that can be costly and subject to dual-use export controls. The SP301Q profiler leverages Colloidal Quantum Dot (CQD) sensor technology to overcome these limitations. CQD sensors, built from nanoscale semiconductor crystals, provide an efficient alternative while delivering performance comparable to InGaAs-based systems.

This approach enables:

- Lower system cost

- Reduced regulatory complexity

- High sensitivity for SWIR applications

- Comparable accuracy and resolution to traditional solutions

Broad Wavelength Coverage: 400–1700 nm

The SP301Q supports beam characterization across a wide spectral range:

Particularly optimized for 1550 nm SWIR lasers

400 nm to 1700 nm wavelength coverage

Compatible with visible, NIR, and SWIR sources

Lasers operating at 1550 nm are widely used due to their eye safety and favorable atmospheric transmission, making them optimal for LiDAR, optical communication, and remote sensing and military applications.

High-Fidelity Beam Analysis

Engineered for detailed beam diagnostics, the profiler combines sensitivity, speed, and dynamic performance:

- High sensitivity for low-signal detection

- Wide dynamic range

- Global shutter

These capabilities enable precise analysis of:

- Beam shape

- Spot size

- Spatial power distribution

Sensor and Imaging Specifications

The SP301Q is designed to balance measurement accuracy with practical usability:

- Active area: 9.6 mm × 7.7 mm

- Resolution: 640 × 512 pixels (VGA)

- Pixel Size: 15µm x15 µm

This format supports detailed spatial profiling while maintaining efficient data handling and integration into laboratory or production environments.

Powered by BeamGage® Professional Software

The profiler is delivered with Ophir BeamGage® Professional, an advanced beam analysis platform widely used in research and industrial settings.

Key capabilities include:

- ISO-compliant beam measurements

- Power density analysis

- Spot diameter and position calculations

- Comprehensive beam characterization tools

BeamGage is built on Ultracal™, a proprietary baseline correction algorithm that contributed to establishing the ISO 11146-3 standard for beam measurement accuracy.

Additional software features include:

- Advanced image processing

- Trend charting

- Data logging

- Pass/fail production testing

- Multilingual interface support

Designed for Integration and Production Environments: LiDAR, Communications, Defense

Beyond lab use, the SP301Q supports industrial deployment through:

- GigE interface for high-speed data transfer

- Seamless integration into manufacturing and test networks

This makes it suitable for inline monitoring, automated testing, and process validation workflows.

Integration into Production Environments

The profiler is engineered for a wide range of photonics and electro-optical use cases, including:

- LiDAR for autonomous vehicles

- Remote sensing

- Optical communications

- Defense and military laser systems

Availability The Ophir SP301Q CQD Beam Profiler is available now.