Measuring Laser Power with a Thermal Sensor:What Happens When the Sensor Heats Up?

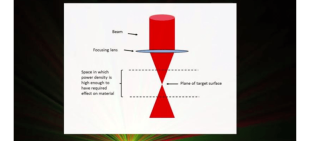

Thermal sensors measure heat.

Lasers heat up these sensors, which is what we want.

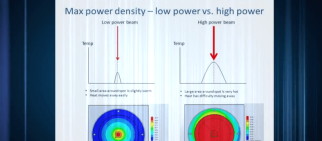

But after the laser is turned off, the sensor might still be hot. (Especially true for high powers, long exposure.)

Does this mean the sensor will still show a reading? Should it be zeroed?

Measuring Laser Power with a Thermal Sensor:What Happens When the Sensor Heats Up? Read Post »