- The physical changes in the laser system will translate into changes in the power density supplied by the laser.

Only through periodic measurements of the laser system as a whole can these changes be managed. Which brings us back to the question: why aren’t these measurements important to the end user? The answer involves a variety of barriers to advancement. Some have been overcome, but some have yet to be fully addressed.

Industrial lasers are typically designed with enough power or energy to process material through joining pieces together, adding material, subtracting material, or changing the physical properties of the material. Historically, it has been difficult to measure these lasers (especially at the laser’s focused spot) because you could very well end up “processing” the measurement equipment during the measurement.

Advances in laser systems and applications have resulted in the increase of laser powers in fiber, disc, and direct diode lasers. Materials that could not efficiently be processed before now can be or soon will be. Materials also can be processed at faster throughput rates. As needed as these advances are, they present a few problems.

First, as laser powers climb, the thermal effects and degradation of the laser system through component contamination and/or aging are amplified. As this degradation happens, changes in the power density take place, with either the reduction of laser’s output power, or changes in the laser’s focused spot size and/or location in relationship to the material being processed.

Second, measurements on higher-powered laser systems have proven to be problematic in the past. Impinging on the beam, either at or before the point of focus will eventually hit a wall because the power density will simply be too high.

Changes in the laser system due to eventual thermal effects will change the process, usually resulting in an inconsistent result, such as a poor cut or a reduction in the joint. If traditional methods of measurement cannot effectively measure the changes in the laser, how can these changes be managed?

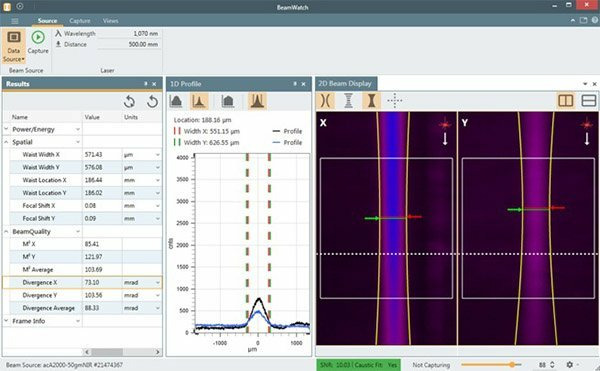

The answer is non-contact measurement in the form of a technological breakthrough – BeamWatch® by Ophir-Spiricon. BeamWatch takes a measurement of the laser by using a camera with a lens to image the Rayleigh Scattering off of the focused beam which gives an image of the laser at and around the focused spot, or the “beam caustic”, without coming in contact with the beam. Since it does not impinge on the beam, the high power density doesn’t damage the measurement equipment; in fact, it actually improves the signal provided for analysis.

Since it is a camera-based system, data points can be taken several times a second and dynamic measurement can be made. These dynamic changes allow the laser user to view and measure the laser’s performance as it happens. Shifts in the location of the focused spot, the size of the focused spot, the M2 of the laser, along with several other critical measurements, can be measured in amount with respect to time. Old Habits Die Hard.

The next barrier is the fact that old habits die hard. When it comes to laser system maintenance, many times there is a “don’t fix what isn’t broken” approach. What some laser users have been doing for 20+ years is still fine for them today. The problem with this approach is that, more than likely, the methods and tools that were used 20+ years ago are not painting a full picture of how the laser is performing. This is especially true when it comes to capturing and analyzing timebased laser characteristics. Legacy equipment such as laser “power pucks”, acrylic mode blocks, and laser burn paper, provide single data points over a short period of time. Today’s systems provide data from beam-on time to several seconds, minutes, or even hours later, giving the laser technician a more complete story of how their laser system is behaving.

Old habits can also hinder the adoption of new equipment. The application of newer laser measurement technologies can be intimidating at first. However, understanding what the laser light is doing (converging or focusing, collimating, diverging), is critical. Once the measurement system is in place on the laser system, navigating and manipulating the software can also be a daunting task. Thankfully, those who develop laser analysis software realizes this and have designed software that is simple and easier to use, and utilizes industry standard measurements and graphics rich presentation of the data being collected for review.

One barrier that seasoned laser technicians will confront, whether they’re willing, able, and eager to apply new measurement solutions or not, is the adoption of new technology. Naturally, there is a tendency to be cautious when new technologies are introduced, because there is the question of whether or not the data that is collected and the results that are produced are accurate. As an example, the introduction of the BeamWatch beam analyzer in 2013 generated these very questions, mostly because the method of generating the signal that is analyzed was new to the industry. From the early design days, these questions were taken into account. Ophir-Spiricon engineers are confident that the data that BeamWatch provides is accurate within +/-5%. This confidence is based on many years of measurement data and experience, mathematical proofs, and a comparison of results with known and trusted measurement techniques. Those who have used the BeamWatch system on their laser system(s) have not only gotten results that they expected, but also have gotten information about their system that they have never captured before.

Ultra-High Velocity

Ultra-High Velocity