Additive manufacturing offers significant advantages across many industries. Delicate components can be produced efficiently and customized to individual needs. Even low-volume production runs can be economically viable. However, efficiency must not come at the expense of part quality.

Measuring the lasers regularly is essential both during development and operation of AM machines. However, this is a challenging task with high-power lasers in additive manufacturing chambers: Conventional water- or fan-cooled measurement systems are difficult to use in combination with metal powder inside the machines. But without these cooling options, conventional instruments require a cooldown period after each measurement.

MKS has focused on laser measurement for LPBF applications. At Formnext 2025, we will showcase Ophir® solutions that deliver consistent measurement results — without the need for cooldown.

Streamline Development, Operation, and Service.

Visit us at Formnext in Hall 12.0, Booth A.101 to experience our dedicated measurement solutions for Additive Manufacturing:

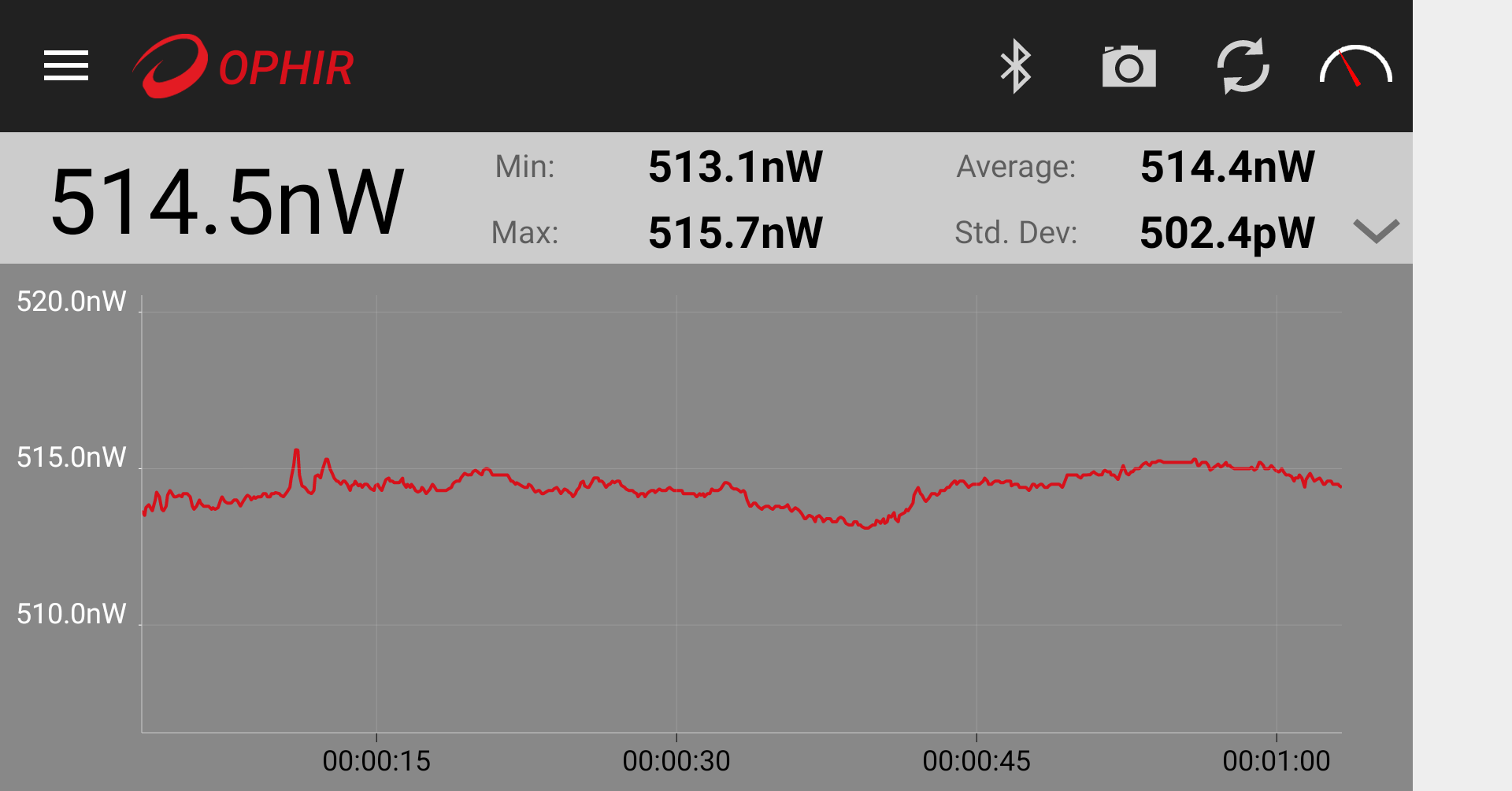

Measure your laser power instantly

Quickly and reliably check your laser power with Ophir Ariel — a miniature power meter. This compact system measures laser powers from 200 mW to 8 kW, covers various wavelength ranges, and is small enough to fit in the palm of your hand. Data can be transmitted directly from the build chamber via Bluetooth or USB. Originally developed for additive manufacturing, the Ophir Ariel is now successfully used in other industries for high-power laser measurement.

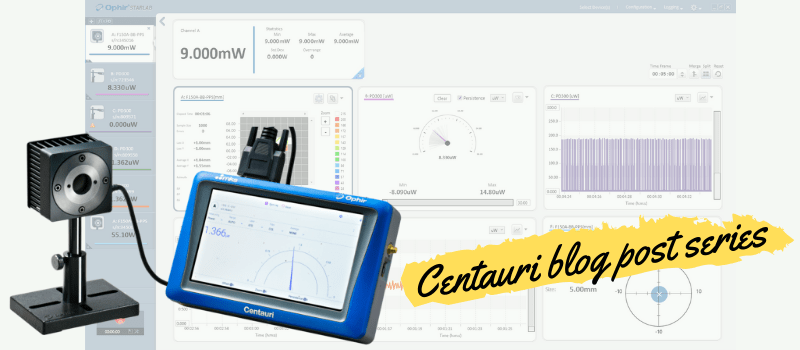

Analyze laser beams fast and accurate

The Ophir BeamPeek® integrated caustic and laser power measurement system delivers reliable results in just three seconds. You get beam caustic, focus analysis, and laser power data without the need of water or fan cooling. The system uses a patented cooling concept based on replaceable cooling inserts. It measures NIR laser powers ranging from 10 W to 1 kW (up to 700 W for green wavelengths). Leading AM system developers rely on this versatile device for both development and service.

See focal shift in real-time

Ophir BeamWatch® AM enables real-time focus spot and position measurements. Based on our non-contact measurement technology, BeamWatch AM delivers beam parameters such as focus size, caustic, astigmatism and Rayleigh length. By quickly detecting whether the beam is properly aligned and focused, it helps maintain process stability and enhances print quality.

Meet Our Experts at Formnext

Whether you’re optimizing process parameters, troubleshooting laser drift, or exploring new quality control methods, our team of laser measurement experts will be there to guide you.

Visit us at the MKS I Ophir booth to see live demos, discuss your challenges, and discover how our dedicated laser measurement solutions can take your additive manufacturing to the next level.

Interested in a free voucher code or meeting with our experts?

Send an email to dagmar.ecker@mks.com to schedule your visit in advance and receive your complimentary Formnext entry voucher.

Leave a Reply

Your email address will not be published. Required fields are marked *