G.E. Slobodzian, Director of Engineering, Retired, Ophir-Spiricon

Part 1: New Camera Technologies

Part 2: Baseline Methods and Mode Effects

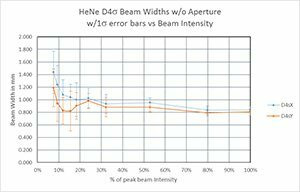

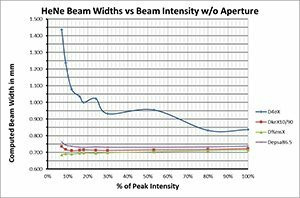

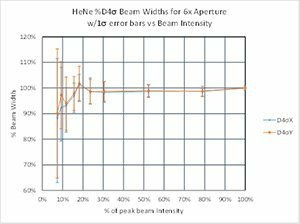

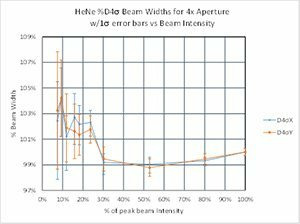

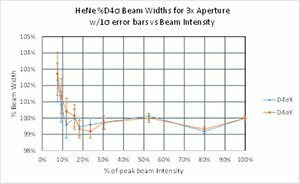

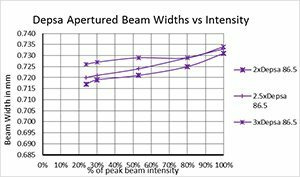

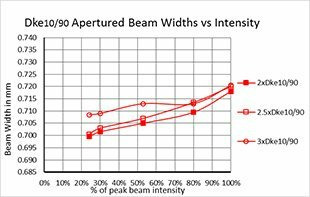

For direct second moment D4σ calculations, providing a proper baseline is only a partial answer. We observed that the noise in the outlying regions surrounding the beam can yield wild frame to frame differences for the same beam. Thus, it becomes imperative to remove this outlying noise to obtain an accurate second moment beam width. The method taught by ISO-11146-3 in 2004 recommended isolating the beam profile with an aperture 3x the second moment beam width. Ten years before this ISO publication, Spiricon was already working on how to resolve this problem and came to a similar but somewhat different result.

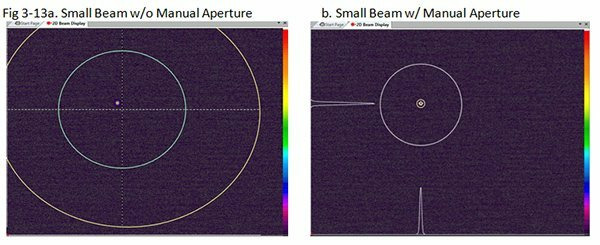

Part 2 demonstrated that the degraded signal to noise of a beam, modelled by a dimming beam profile, caused the second moment beam width results to gyrate wildly around its true value. In a similar way, reducing the size of the beam relative to the camera imager will have the same effect.

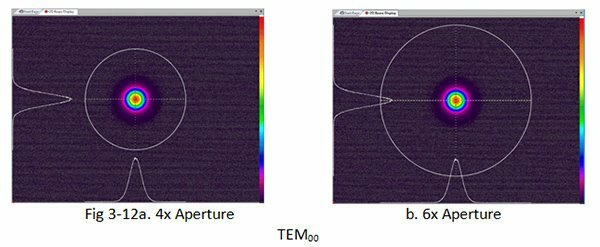

Part 3 will investigate the aperture selection process using a state of the art CCD camera connected via a USB2 serial port. The camera is a Spiricon SP620 that outputs a 1600x1200 12 bit per pixel image format. The pixel pitch is 4.4μm² and the camera has a dynamic range of ~60dBrms. Real cameras will create outputs not quite as perfect as we modelled using the BeamMaker™ utility. The modelled beams and the modelled noise were mathematically perfect. The black level and noise of a real camera is a bit more complex.

Most cameras output some degree of imager shading and pixel to pixel offset variation. Temporal noise is reasonably Gaussian in distribution and is made up of imager, readout, amplifier, and digitizer noise. The readout noise will possess some random flutter in its distribution. This flutter can be observed by watching a histogram of the corrected baseline. Thermal effects can also be observed. The signal to noise tends to deteriorate with increase in temperature. And the black level baseline will also drift with temperature. Depending upon the camera design, some amount of power supply noise may also be observed in a black background. Cosmic rays passing thru the imager can generate false signals on one or groups of pixels.

No matter the source of the noise, the end result is that it is not possible to create a perfectly stable background using a real camera. What this means is that the background noise baseline will statistically bounce around a zero point, but never be zero. If camera temperatures are fluctuating, the baseline will also be observed to drift with the changes in imager temperature.

Figure 3-1 is a screen shot of a HeNe laser beam on the full size imager of the SP620. The beam’s peak intensity is just below camera saturation. The camera baseline has been Ultracal’d with the background indicating negative noise as a light grey and positive noise as dark purple.

Ultra-High Velocity

Ultra-High Velocity