These beams are not so powerful that they will damage or destroy typical absorptive filters. In fact, it is possible to stack up a sufficient optical density to reduce the power of a 1W laser to the nW levels that will not saturate the detector. Unfortunately, doing this will more than likely result in erroneous measurements. This is due to a phenomenon called thermal lensing, or thermal blooming. The laser’s energy heats the local area of the absorptive filter, changing its optical properties. These changes often result in changes to the refractive index of the substrate, forming a lens that may either focus or expand the beam. At lower powers, this phenomenon can be observed over discernable timeframe, hence the term “blooming.” However, it may also occur almost instantly, giving the illusion of stability and accurate measurements.

There is a rule-of-thumb that says that absorptive filters may be used safely and accurately at powers that are around 100mW per mm diameter. This is roughly equivalent to a power density of 12.7W/cm2. Since power density increases as beam size decreases, this means that a 100μm beam may show this effect at as low as 1mW of power. Of course the actual values will vary and be dependent on the wavelength. One thing is certain, though: accurate measurement with a camera array requires proper attenuation.

Proper attenuation uses a combination of reflective and absorptive filters to reduce the beam power to the array. The first stages of attenuation should always be done with some type of reflector if the power density is likely to exceed the thermal lensing limits. These can be mirrors, prisms, or front surface reflectors. If polarization is important then these reflectors should be used in pairs to maintain the polarity of the laser beam.

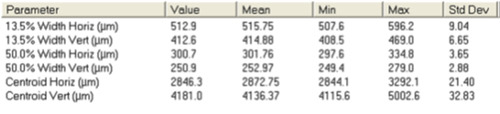

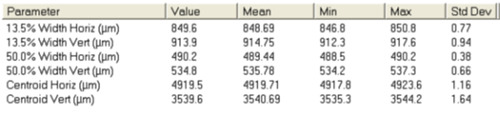

In this article we will show results from measurements of moderately powered lasers (300-500mW) made with absorptive filters alone, combined reflective and absorptive filters, and with the NanoScan slit scanning profiler, which requires no attenuation for such measurements. The error in the measurements made with the absorptive filters alone is quite significant, with the beam size being underreported by as much as 30%.

An unfocussed CW beam from a Coherent DPSS 532 Laser (532nm wavelength) with a nominal power of 500mW was measured using three methods. Method 1: Using the camera array beam profiler with all the attenuation provided by absorptive filters, the beam was measured at a point 30cm from the exit aperture of the laser. The attenuation comprised a 2.8OD gray-glass fixed filter and the Photon ATP-K continuously variable wedge attenuator (1.7—4.6OD). Method 2: The first stage of attenuation was provided by using a front surface reflection with additional attenuation provided by the ATP-K. The rest of the measurement set up remained identical to that in Method 1.

Method 3: Measurements were then taken at the same measurement plane with the Photon NanoScan scanning slit profiler, which needed no attenuation for this laser power.

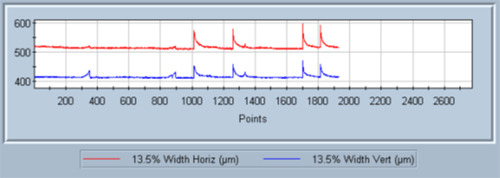

Because we expected to see thermal effects in the initial experimental design (Method 1), we used time charting to observe the measurement of the laser. In order to see any effects and eliminate any contribution from the laser itself, we started the camera and then uncovered the laser beam. There was an immediate spike of the beam size to around 700μm. It settled to a value around 500μm (1/e2) within a few milliseconds. With each measurement we saw a similar pattern, however the value of the initial spike was somewhat variable.

Ultra-High Velocity

Ultra-High Velocity